|

|

|

|

|

|

|

|

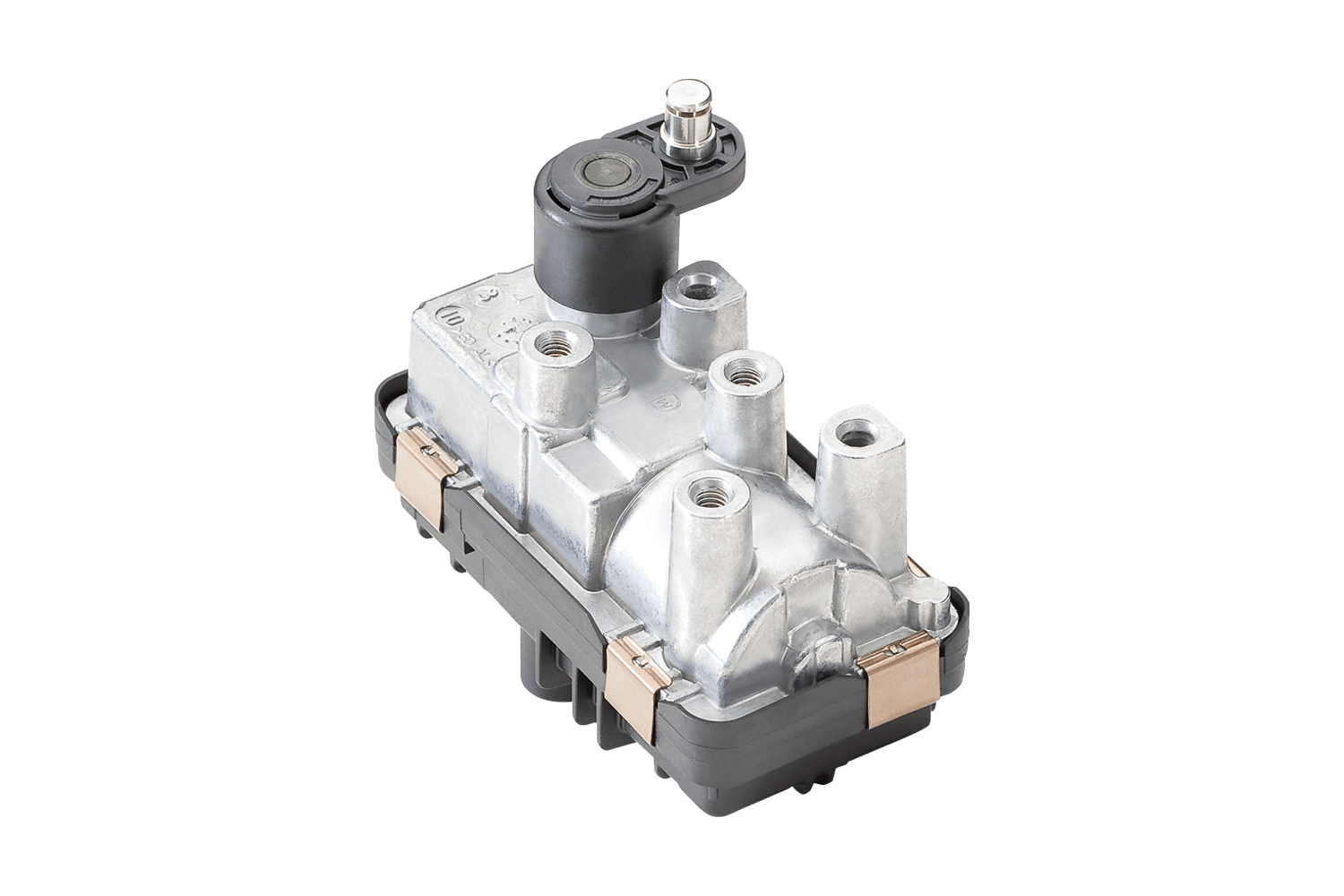

Rotatory smart actuators for high temperatures

The optimum setting for the turbo: The HELLA rotatory smart actuators for high temperatures, together with the control unit, ensure that the turboshaft is always precisely in the right position in turbocharger technologies such as VNT (variable nozzle turbo) or VTG (variable turbo geometry).

The integrated electronics consist of a CIPOS® (contactless inductive position sensor), a position sensor, the motor control, and a component for fault diagnosis. Thanks to the position sensor and the CIPOS technology developed by HELLA, the position of the turboshaft is continuously recorded, reliably calculated, and actively passed on to the engine control unit. The CIPOS is magnetically resistant, temperature stable, and inductive. The angle of the turbocharger is determined free of contact, free of wear, and with a high measurement accuracy.

The fault diagnosis component integrated in the rotatory smart actuators for high temperatures allows faults to be quickly detected, reported back, and any necessary control interventions to be made. The energy-efficient HELLA rotatory smart actuators for high temperatures convinces with its flexible operating angle range, which allows controlled movements up to the end stop. Communication is done via pulse width modulation (PWM) or the controller area network (CAN).

The optimum setting for the turbo: The HELLA Universal Turbo Actuators (UTA), together with the control unit, ensure that the turboshaft is always precisely in the right position in turbocharger technologies such as VNT (variable nozzle turbo) or VTG (variable turbo geometry).

The integrated electronics consist of a CIPOS® (contactless inductive position sensor), a position sensor, the motor control, and a component for fault diagnosis. Thanks to the position sensor and the CIPOS technology developed by HELLA, the position of the turboshaft is continuously recorded, reliably calculated, and actively passed on to the engine control unit. The CIPOS is magnetically resistant, temperature stable, and inductive. The angle of the turbocharger is determined free of contact, free of wear, and with a high measurement accuracy.

The fault diagnosis component integrated in the UTA allows faults to be quickly detected, reported back, and any necessary control interventions to be made. The energy-efficient HELLA UTA convinces with its flexible operating angle range, which allows controlled movements up to the end stop. Communication is done via pulse width modulation (PWM) or the controller area network (CAN).

Rotatory smart actuator for high temperatures.

CIPOS® technology

Technical Data

| Rated voltage | 14 V |

|---|---|

| Operating voltage | 10.5 – 16 V |

| Operating temperature | -40 °C to +125 °C |

| Short-term Maximum temperature | Up to 150 °C |

| Max. torque (13.5 V; RT) | < 9 A |

| Operating angle range | 100° |

| Angular velocity (at 20 Ncm) | > 0.35°/ms |

| Min. torque (at 14 V, 0.1°/ms) | > 55 Ncm |

| Sensor resolution | 0.125° |

| Position tolerance over angle range | +/-2% |

| Protection class | IP 6K9K |

| Protocol | CAN or PWM |

Program Overview

| Variant | Operating angle | Part number | Packaging unit |

|---|---|---|---|

| Turbo actuator, torque > 55 Ncm | 100° | On request | 1 |