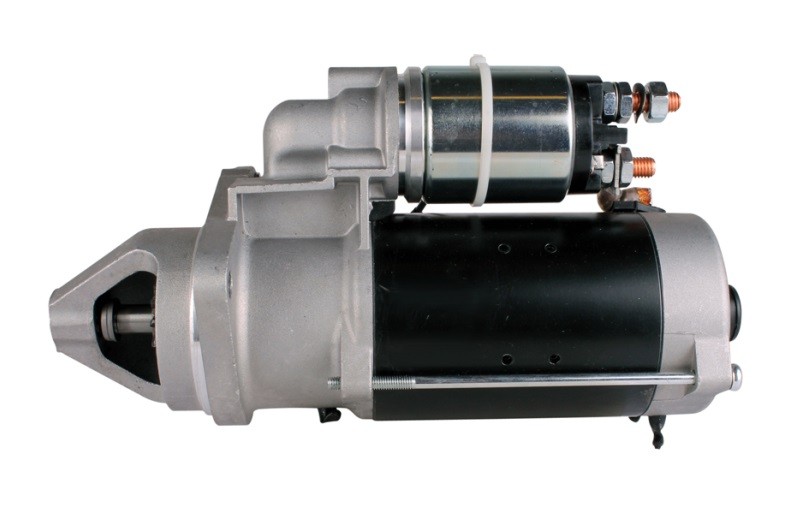

The starter does not turn when the ignition switch is actuated.

| Cause: | Remedy: |

| Switch on lighting (low beam). | |

Lighting weak or not working =

|

|

| Solenoid switch does not energize: Bridge terminals 30 and 50 on the starter, Starter runs / engages =

|

|

| Solenoid switch energizes: Remove battery cable from terminal 30 on the starter and connect directly to the contact screw below connection terminal 30. Starter starts up =

|

|