Particulate matter from brakes: New coatings help

The Euro 7 standard also regulates particulate emissions during braking. HELLA relies on innovative brake technologies to reduce the emissions.

Today, around 80 to 85 percent of particulate emissions from cars result from tyre and brake wear, road abrasion and dust being disturbed. For this reason, alongside exhaust emissions and tyre wear, the new Euro 7 standard also regulates particulate emissions when braking. The challenge here is defining a measurement strategy that allows different vehicles to be reliably compared on the relevant test benches. The development of new friction linings and specially coated brake discs ensures a reduction in particulate emissions. The Euro 7 standard will apply from 29 November 2026 for newly type-approved passenger cars and from 29 November 2027 for all newly registered vehicles (class M1)

Euro 7: Limits on the amount of particulate matter during braking

The publication of the Euro 7 Regulation in the Official Journal of the European Union (2024/1257) includes limits on particulate mass. For vehicles with combustion engines, hybrid or fuel cell cars, the limit is seven milligrams per kilometre. Pure electric cars have lower brake wear due to their design, particularly due to recuperation of braking energy, which reduces the load on the brakes. That is why the limit for pure electric vehicles is three milligrams per kilometre. From 2035, the standardised value should be three mg/km across all vehicle classes, according to the Euro 7 regulations.

Less particulate matter: Brakes made from innovative materials with special coatings

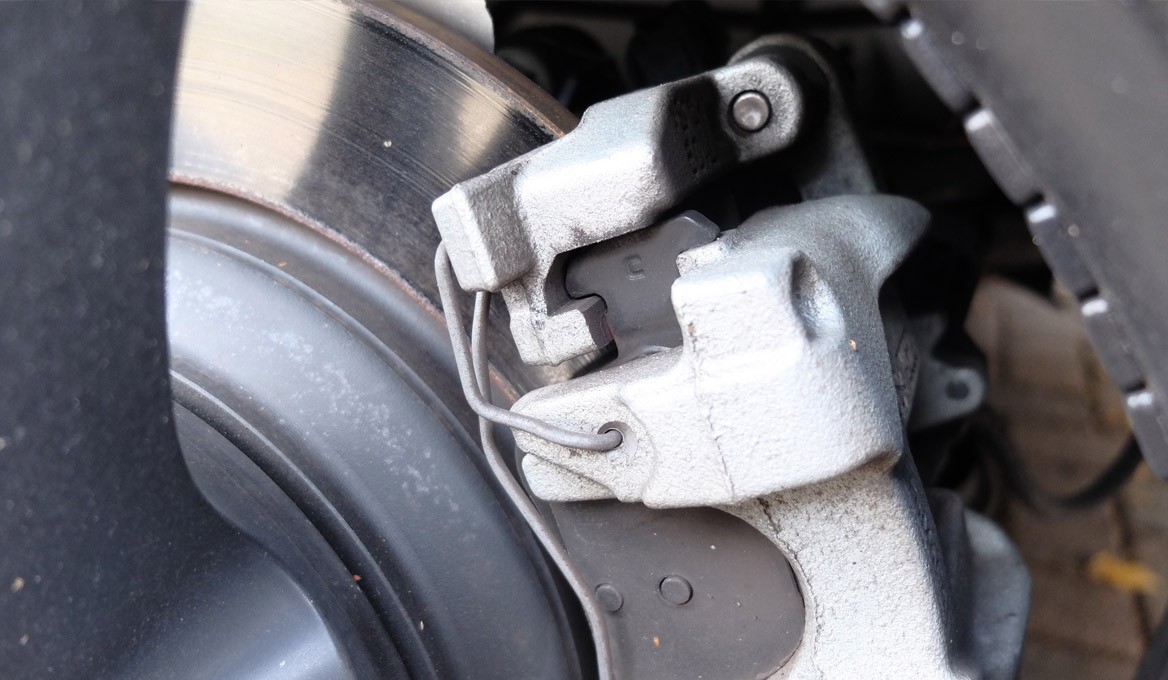

A vehicle must have optimal and comfortable deceleration and slow down as quickly as possible in the event of danger. This inevitably creates friction. Yet friction generates heat and causes the friction partners to wear, which particularly affects the brake disc. This means that particulate matter is emitted. Filtration specialists have actually already presented filter systems that are arranged around the brake discs and are designed to trap brake dust. However, it is much more effective to avoid particulate matter by continuously developing the brake components and using new material compositions. For example, new coating processes for grey cast iron brake discs are used in conjunction with customised friction lining composites.

HELLA is constantly working on developing new friction materials and surfaces in order to generate an optimum balance between brake performance, durability and low particulate emissions. The focus here is the requirements that the specific vehicle has for the braking performance, i.e. is it a small car, a mid-range car, an SUV or a 'super sports car'?