Checking the voltage supply

Check the voltage supply with the ignition switched on.

- Measured value: 11 – 14 V.

Note:

An Ohm measurement must only be carried out in a de-energized state (plug connection removed).

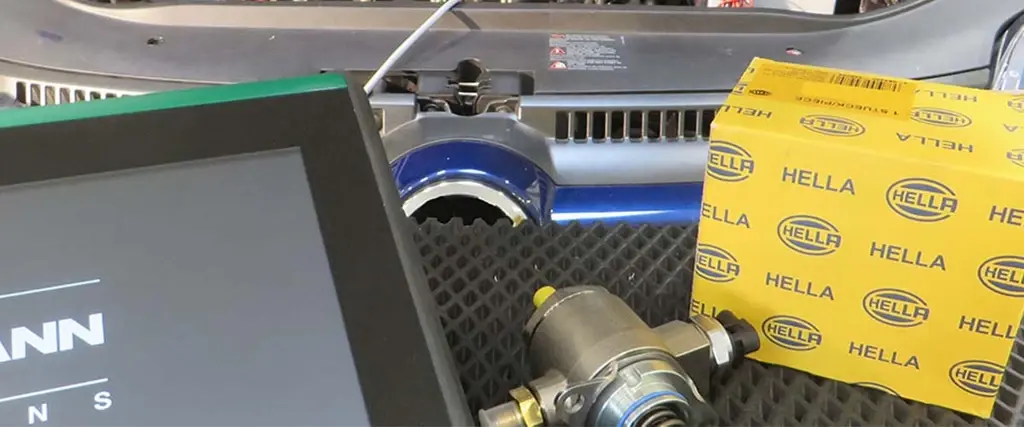

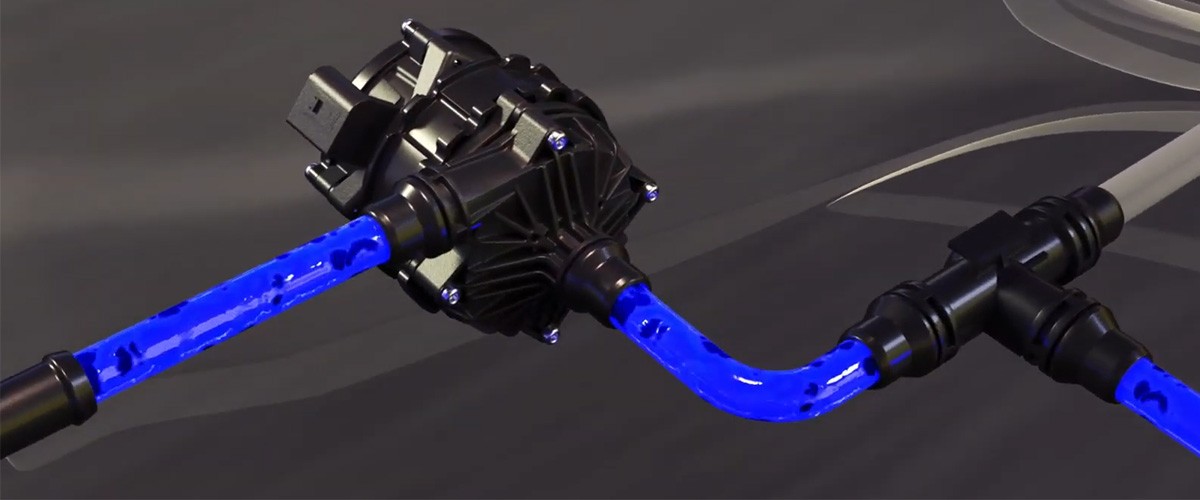

The idle speed controller ensures that the idle speed of the engine remains constant in all load conditions. On this page you can find out about how the idle speed actuator regulates the intake air mass of the engine, and how the failure of this actuator impacts on the engine running. Practical tips for troubleshooting and assembly instructions help to quickly rectify defects relating to the idle speed controller.

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

A faulty idle speed actuator can manifest itself as follows:

Causes for failure of the idle speed actuator can be:

Check the voltage supply with the ignition switched on.

Note:

An Ohm measurement must only be carried out in a de-energized state (plug connection removed).

Use the multimeter to measure the coil resistance between the two connection pins of the idle speed actuator.

Check the coil for a winding short circuit between the two connection pins.

Check the coil for a winding interruption between the two connection pins.

Check the coil for short circuit to frame – between pin 1 and component housing, and between pin 2 and component housing.

Unscrew the servo unit from the housing. Visual check to determine whether the bypass opens and closes when the valve rod is actuated.

Read out fault code.

ASSEMBLY INSTRUCTIONS

Before mounting the idle speed actuator, the supporting surface must be cleaned and, if necessary, the flange seal must be replaced.

Observe the tightening torque!

Please observe the specifications provided by the respective vehicle manufacturer.

How helpful is this article for you?

Success

Success

Success

Success

Error

Thank you for your feedback!

Wrong Captcha

Something went wrong

Benefit from consenting to our cookies ‒ we use cookies to:

By clicking on "I agree", you consent to the placement of cookies.

You can find out more about the cookies used by HELLA websites in our Cookie Policy .

Our cookies do not contain any personal data.

For more information, see our data protection notice.

Great! Just one more Step

Head to your inbox and confirm your email address so that you don’t miss our updates!

Get ready for brand new technical videos, car repair advice, trainings, helpful diagnostic tips, marketing campaigns and much more... delivered straight to your inbox every two weeks!

Sign up for our free HELLA TECH WORLD newsletter to receive the latest technical videos, car repair advice, training, marketing campaigns and diagnostic tips.

Together we can get cars back on the road quickly!

Success

Success

Error

Please note: You will only be subscribed to the newsletter once you have clicked on the confirmation link in the notification e-mail you will receive shortly! Data Protection | Unsubscribe