High voltage in the automotive workshop: are you in a good position?

How many electric cars are there in Germany

According to the Federal Motor Transport Authority (KBA), 44.2 percent of all new passenger cars registered in Germany from January to July 2022 were equipped with alternative drive systems (BEV, hybrid, plug-in hybrid, fuel cell, gas and hydrogen). Compared to the same period last year, the share of alternative drive systems has risen by an impressive 13 percent. At 24.9 percent (+10.2 percent), new cars with an electric drive (BEV, plug-in, fuel cell) accounted for about a quarter of all new registrations. Battery-electric passenger cars achieved a 13.6 percent share of new registrations in the reporting period, an increase of 27.1 percent. Looking at the figures for Europe as a whole, sales of battery electric vehicles in the EU continued to grow in the second quarter of 2022, accounting for 9.9 percent of total passenger car registrations.

High voltage training in the automotive sector: Qualifications are everything

Disconnecting HV vehicles: practical knowledge

In addition to basic technical knowledge and qualifications, you must have practical knowledge if you want to work on high-voltage vehicles. One key topic, for example, is disconnecting the HV system. When doing so, not only do you need to follow the "five safety rules", but you also need to have knowledge of different manufacturer specifications and special solutions. The HV system can only be safely disconnected (service disconnect) if the manufacturer's instructions are followed.

The five safety rules for working on high-voltage vehicles

Working on high-voltage vehicles

Potential danger

During repair or service work in the workshop, live parts being touched by the mechatronics technician can never be completely ruled out. This particularly applies to vehicles that have been in accidents. Inattention or the wrong move on high-voltage vehicles (from 60 V DC or 30 V AC) can quickly have dangerous consequences for health. Thus, as few as 50 volts are sufficient to cause a life-threatening current of 50 mA (milliamperes) to flow. The danger depends on the holding time and the individual physiology of the mechatronics technician, and the human body resistance, which is approximately between 700 and 1,000 ohms. This makes it all the more important to observe the safety precautions during service and repair work (accident prevention regulations BGV/GUV-V A1, A3). The car manufacturers' specifications must be strictly observed.

High-voltage workshop equipment

Appropriate tools are also prescribed for work on high-voltage vehicles. Therefore, the specifications of the DIN standards VDE 0105-100, DIN 0100-10 apply. VDE-tested tools that guarantee insulation protection up to 1,000 V are required. All hand tools, including torque wrenches or ring spanners, must be individually tested according to IEC 60900 based on their insulation. A suitable voltage tester (according to DIN VDE 0682-401) or the measuring equipment approved by the relevant vehicle manufacturer is required to determine that there is no voltage present. And, what's more, numerous tool manufacturers offer complete tool trolleys with the relevant HV tools. In addition, there is appropriate protective equipment consisting of insulating gloves, insulating mat and eye protection.

It is also essential that the workplace is secured and that the car is specifically marked as a high-voltage vehicle using a 'cone'. It is best to define a fixed workplace that you can secure with barrier posts, including straps or scissor barriers if necessary. This way, the required equipment can also be placed within easy reach, and attention is not drawn away by having to look for tools unnecessarily. A standing desk, including a computer on which you can retrieve information relevant to the vehicle, completes the workshop equipment. Installing a wall box on the workshop premises also makes sense. This way you can offer your customers the 'full' service.

High-voltage components of electric cars

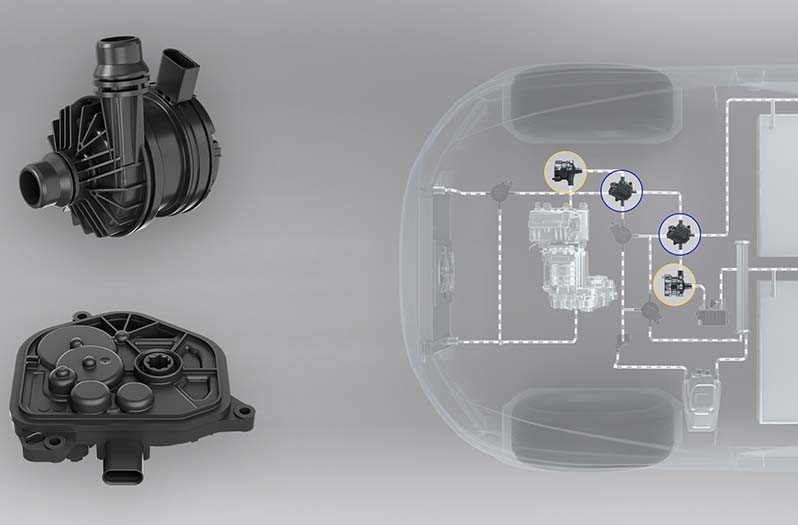

Electric vehicle thermal management

High-voltage PTC air or water heaters are usually used to heat the interior in winter, and in many cases a heat pump is also used. Furthermore, the waste heat from the electric motors and the battery packs is also used today. Ultimately, the aim is to protect the high-voltage batteries as much as possible so as not to negatively affect the vehicle's range.

All these systems need to be maintained. For example, using the right coolant also plays a role. "Regularly servicing the thermal management system is the oil change of the future," expert Andreas Lamm says in a specialist article found on the industry portal at www.krafthand.de.

Why does an electric car have a 12 V battery?

The classic 12 V vehicle battery also plays an important role in electric vehicles. It supplies the vehicle's low-voltage system and ensures, for example, that the central locking system, the interior lighting, the on-board computer and, most importantly, the control units function correctly. This also includes windscreen wipers, lighting or steering assistance systems. Ultimately, it serves as a back-up to maintain key safety functions in the electric vehicle if the high-voltage system fails. And by the way, electric cars have no alternator. A DC converter charges the 12 V battery.

High-voltage vehicles in your workshop: work more on communication

Can you also do "electric"?

When an appointment is scheduled at your workshop, your customers have known for a long time that they can trust you as a professional. It is usually irrelevant which vehicle model, engine or version is involved. But does this also stretch to electric vehicles? In actual fact, many independent workshops have to communicate more: many customers do not know that they can also do "electric".

Exciting perspectives

It is a fundamental business decision to embrace high-voltage vehicles. At the same time, a new, additional business field with reliable growth potential is opening up. Deciding on this goes hand in hand with staff having the appropriate qualifications, investing in the appropriate workshop equipment and being willing to have an external independent audit carried out. Ultimately, it also makes a statement to your own employees: "We are open to technology, looking ahead and securing jobs for the future". However, such commitment only pays off if the workshop customers are aware of it.

In the end, communication comes into play!

They still exist, good old invoices, cost estimates, advertising e-mails to existing customers or business cards, all in paper form. So you can also change your traditional means of communication and put your "exciting" message in place. Of course, this also applies to other advertising media and especially to your internet presence. According to the latest DAT report, 17 per cent of potential workshop customers have used the Internet in advance without prior knowledge when they had a service or repair requirement. All in all, the broader you communicate, the better you will be found. Authentic and open communication, whether using short background stories on social media or in a self-made video, using the motto "We can also do electric", also generates support and credibility and definitely connects you with new customers!