Toothed belt / coolant pump kits | HELLA

General

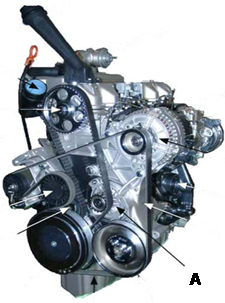

When replacing the toothed belt, all components of the belt drive should be replaced with it. For this purpose, Hella offers complete kits (Fig. 1) including coolant pump, toothed belt, as well as any tension, deflection, and guide rollers that may be needed, and dampers and seals. This eliminates the time-consuming search for individual components. The complete replacement of all components provides maximum protection against subsequent repairs and warranty issues. All parts are optimally aligned with each other and meet the high Hella quality standards.

Design/principle

The toothed belt, also called timing belt, is a transmission belt provided with a serration. It propels the toothed pulleys of the crankshaft and camshaft positively and is responsible for compliance with the timing requirements.

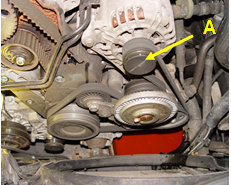

In many vehicles, toothed belts are also used to drive coolant pump (Figure 2, Pos. A) and other auxiliary units. Various tension and guide rollers are responsible for the tension and guidance of the belt. The actual force transfer by the belt is done by an embedded tensile cord which usually consists of aramid or glass fibres. To protect the teeth consisting of elastomer from wear, the inside of the belt consists of abrasion-resistant fabric.

In special types, teeth are provided on the inside and outside of the belt.

Effects of a failure / causes

The belt must be replaced at the intervals specified by the vehicle manufacturer. Failure to observe the replacement intervals or installation instructions bears the risk of damage to components and the engine.

Damages and their possible cause:

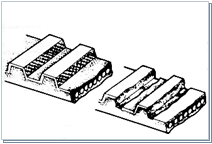

Damaged teeth (Drawing 1):

- Toothed belt too loose

- Exposure to foreign bodies

- Tension too high

- Stuck tension roller

Cracks on the back of the belt (Drawing 2):

- Toothed belt tensioned too much

- Guide roller stiff

- Belt too old

Worn toothed belt edges:

- Belt is running against pulley

- Belt is not aligned

- Defective belt pulley

Toothed belt is flapping/running out:

- Belt too loose

- Tension roller improperly adjusted

Toothed belt torn (Drawing 3):

- Tension too high

- Foreign bodies in the belt drive

- Toothed belt kinked during installation

- Overaged

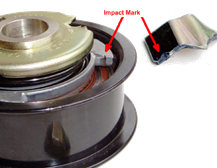

Broken base plate (Figure 4):

- Incorrect basic setting of the tension roller

Various noises:

- Whistling noise by excessive belt tension

- Grinding noise by bearing damage

- Load fluctuation noise by defective torsional vibration damper

- Tooth belt hits against cover

Notes on removal and installation

Always follow the instructions on the product leaflet and special installation instructions of the vehicle manufacturer when replacing the toothed belt kit.

For a correct installation, the necessary special tools should be used.

Check the operationability and condition of alternator freewheeling (Figure 5, pos. A) and torsional vibration damper (Fig. 6), if any, when replacing the toothed belt. Furthermore, the components of the secondary drive (flat belt with tension and idle roller, tensioner) should also be checked. If it turns out during the replacement of the coolant pump that the cooling system is contaminated, it must be flushed. This can be done, e.g., with cooling system cleaner 8PE 351 225-841. The cooling system should only be filled with a coolant that meets the specifications of the vehicle manufacturer. The system must be filled or vented according to the instructions of the vehicle manufacturer.

For information on use, specifications, and change intervals of coolants, see the appropriate Technical Information “Coolant”.

For information on the proper installation of coolant pumps, see the relevant Technical Information.

Finally, attach the service sticker documenting the belt replacement visibly inside the engine compartment and also record the replacement of the toothed belt in the vehicle's service booklet.