Oil coolers for hydrodynamic retarders | HELLA

General

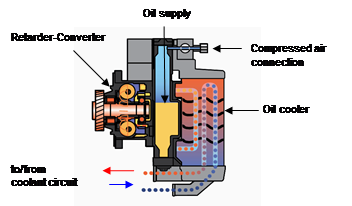

Hydrodynamic retarders (working with liquids) are used in commercial vehicles in order to support the actual brake system as an almost wear-free hydrokinetic brake. The kinetic energy is turned into heat through the deceleration caused by the flow speed of the oil, and this must be transferred back to the cooling system via a heat exchanger (Fig.1). The use of the retarder is either activated by the driver or works automatically. The braking power reaches several hundred KW.

Figure 1

Besides the service brake of a commercial vehicle, which usually is a friction brake subject to wear, vehicle manufacturers increasingly use additional, wear-free deceleration systems.

All variants have several common goals:

• Minimise wear of the service brake

The oil cooler, which is made of solid aluminium or steel, is flange-mounted to the retarder and returns the heat it absorbs to the vehicle coolant circuit. In order to avoid exceeding the preset temperature limit, a temperature sensor for monitoring the coolant temperature is installed near the oil cooler. The sensor ensures that the retarder is reduced or switched off when the temperature limit is exceeded.