Brake hoses and brake lines | HELLA

General information

In hydraulic brake systems, brake hoses and brake lines are used to transfer brake fluid. Brake lines connect the actuation device, such as the brake master cylinder, to the hydraulic components of the wheel brake. Brake hoses are used as flexible connecting lines in all moving areas between the body and chassis.

With the integration of ABS-ESP and TCS systems in modern vehicles, the operative requirements placed on these components have risen dramatically.

Included among the main requirements are compressive strength, mechanical load-carrying capacity and thermal and chemical resistance.

Requirements

Brake hoses are subjected to the following influences:

- Vehicle steering and suspension movements

- Weather (heat, cold, ozone)

- External influences (water, road salt, oil)

- Pulses of hydraulic pressure

As a result of these influences, brake hoses need exceptional pulse strength, robust connecting elements and high fatigue strength.

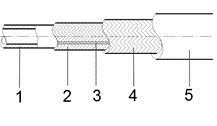

The structure of a brake hose

Brake hoses comprise a special rubber mixture and integrated braiding that considerably improves the strength of the hose and serves as a pressure support.

1. Inner tube

2. Initial reinforcement fabric

3. Special adhesive layer with embedded color code

4. Second reinforcement fabric

5. Hose cover

Causes of failure

Defect

- Bubbles forming where the tap and the braided hose join

Cause

- Leak in the hose sheathing

- Incorrect installation or mechanical overload

Defect

- Cracks forming in the hose cover

Cause

- Aging

- Incorrect installation or mechanical overload

Defect

- Oxidation, corroded lines

Cause

- Aging

- Insulating layer damaged due to environmental influences

Troubleshooting

Brake lines and brake hoses are safety-relevant components and should be checked every time the vehicle is maintained. Typical defects include corrosion on the brake lines and damage to the hose lines. These defects can be caused by accidents, improper assembly or aging.

By carrying out a visual inspection, it is usually possible to detect cracks, bubble formation, corrosion or other external damage with minimal outlay.

Assembly instructions

The following points should be taken into account by the technician when carrying out a repair:

- Mount brake hoses in a tension and contact-free manner

- Avoid twisting the hose and causing chafe marks

- Avoid contact with mineral oil and grease

- Ensure sufficient clearance for steering and suspension movements

- Avoid routing in the direct vicinity of exhaust systems

- Avoid excessively small bending radii (> 40 mm)

Note

Always observe the assembly instructions provided by the brake and vehicle manufacturers in the situations described above.

Improper installation can negatively impact the driving characteristics of the vehicle and endanger lives.