Testing an electric vacuum pump

Because the brake system is one of the most important systems in every vehicle, it is imperative to ensure that a constant and effective brake force is present at all times. The majority of brake boosters uses the vacuum generated by the internal combustion engine’s intake section. But under certain operating conditions, for example during the cold start and warm-up phase or when driving at extreme altitudes, the vacuum produced by the engine is no longer sufficient. In such cases, an additional vacuum pump is required in order to generate an alternative or an extra vacuum.

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

Service information for an electric vacuum pump

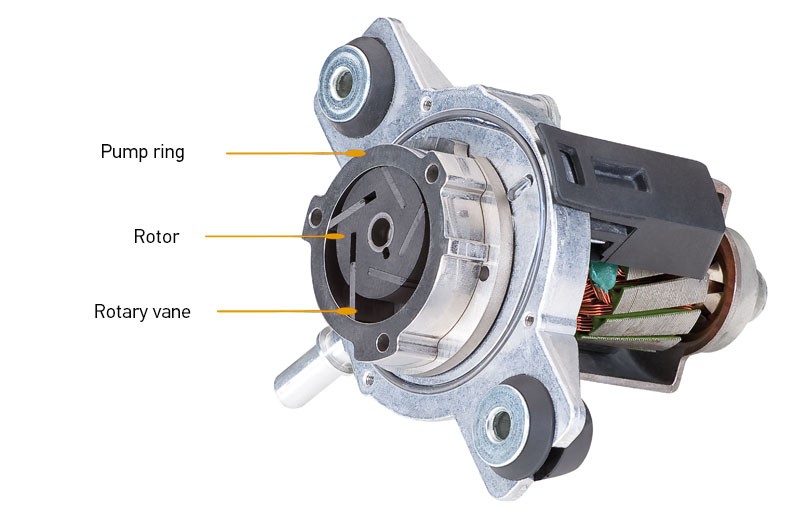

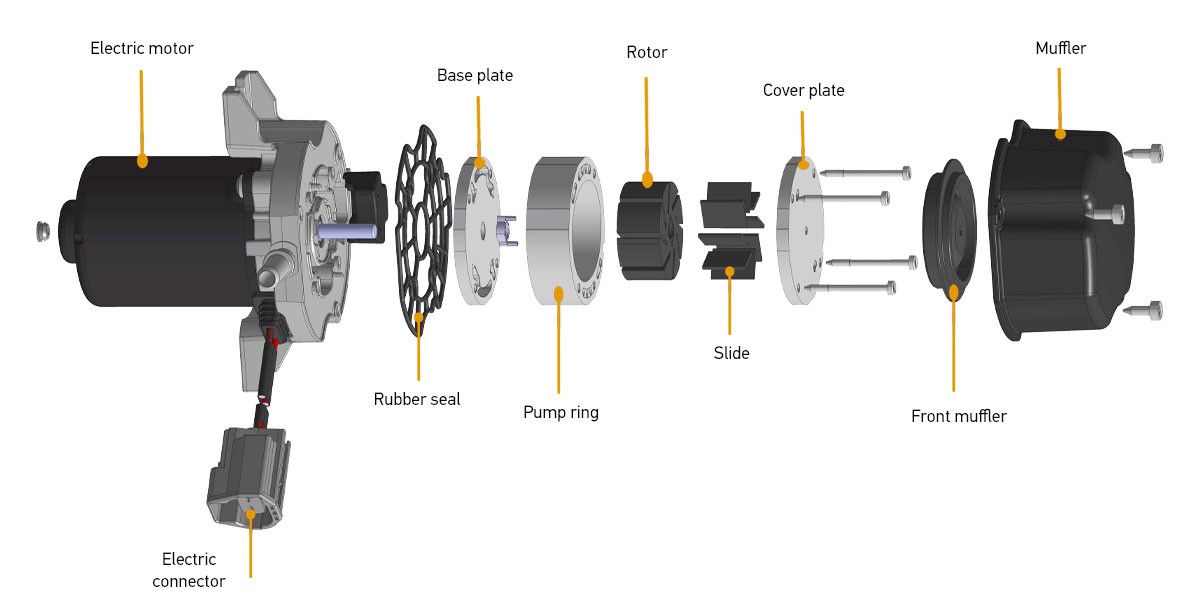

Construction/design of an electric vacuum pump

For vehicles whose engine geometry means that they have too little or no vacuum at all to operate the brake system, electric vacuum pumps are used in order to ensure the reliable operation of the brake booster. The electric vacuum pump guarantees that the reliable operation of a brake system functioning with pneumatic brake boost is maintained.

Electric vacuum pumps can be used in the following engine types:

- Petrol engine with direct injection

- Diesel vehicles

- Hybrid and electric vehicles

- Fuel cell/electric vehicles

- Vehicles with or without turbocharger, automatic transmission or STOP-START system.

Advantages of an additional electric vacuum pump:

- Supports all engine types

- Reduces energy requirements thanks to on-demand pump operation

- Helps to reduce CO2 emissions

- Functions independently of combustion engine technology

- Maintenance-free (dry running and self-lubrication require no connection to the oil circuit)

- Electrically driven vacuum pumps support a flexible vehicle platform concept

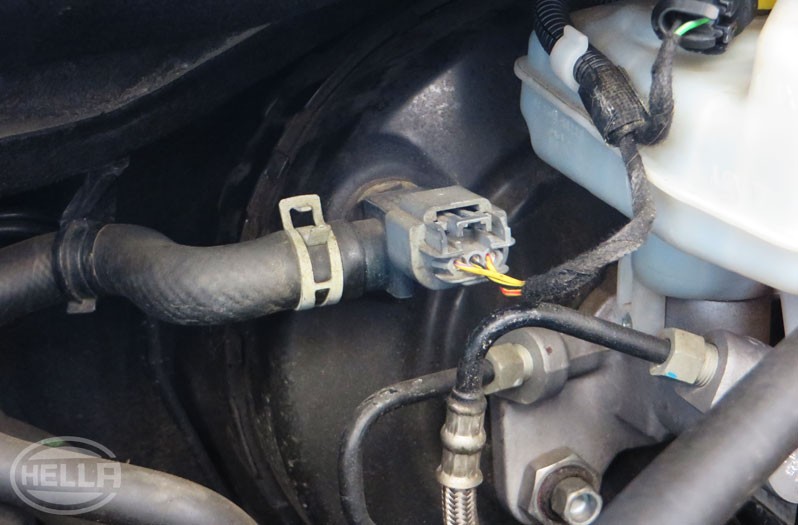

Pneumatic connection

The electric vacuum pump is connected to the flexible pneumatic brake line system via a suction nozzle. The sucked-in air is filtered and moves from the passenger compartment to the vacuum pump via the brake booster and the flexible line system. The pneumatic lines, valves and the brake booster must be free of particles and all types of contamination which, if drawn in, can lead to pump damage.

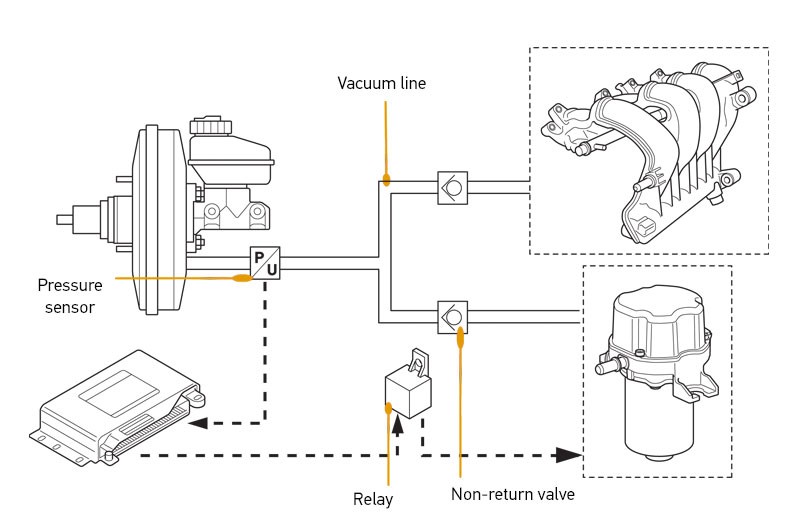

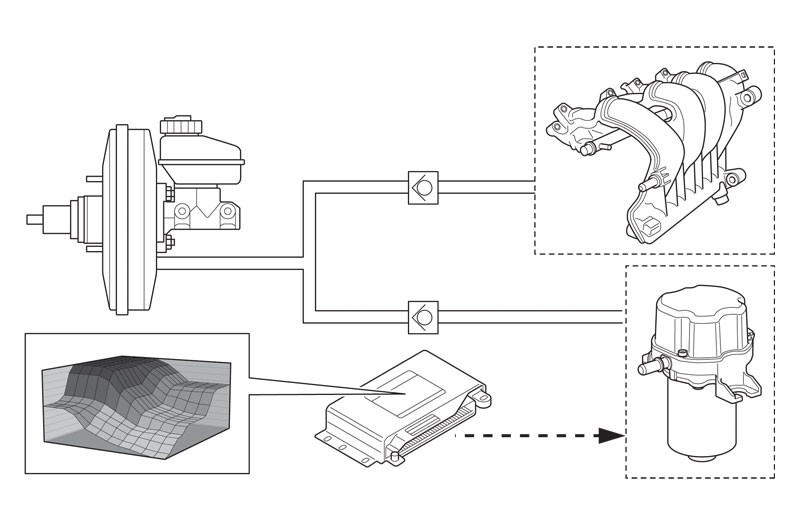

Connection variants / system overview

Depending on the type of vehicle and on the required use, there are two kinds of vacuum pump variants which can be installed. This is where we differentiate between controlled and regulated electric vacuum pumps.

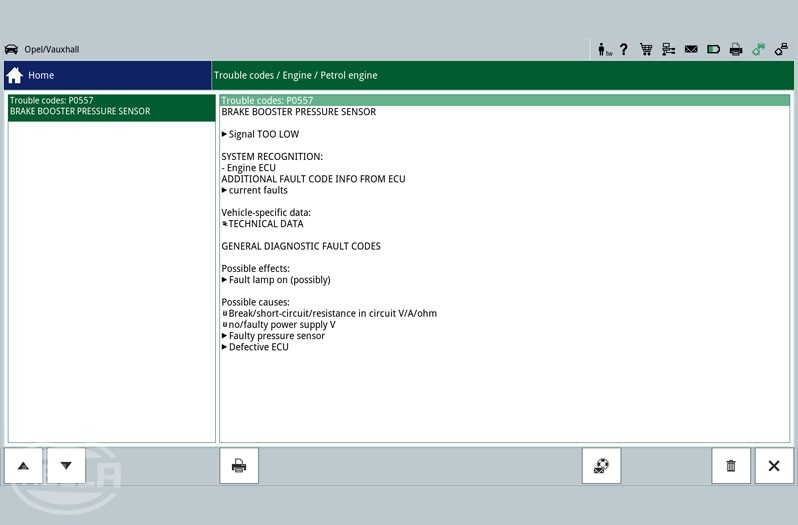

Effects and causes

The following effects can result when failure of an electric vacuum pump occurs

- Vacuum in the brake booster too small

- Poor braking function

- Increased effort needed when brake pedal is activated

- Fault lamp lights up (system-dependent)

The following causes can be responsible for the failure of the electric vacuum pump

- Voltage supply faulty

- External damage

- Defective electric motor

- Vacuum lines damaged or contaminated

Testing electric vacuum pumps and fault diagnosis

A simple functional check of the electric vacuum pump can be performed in the vehicle in the following way.

- Park vehicle in a safe location

- Put the parking brake on

- Switch on the ignition. Start the engine and allow it to run in idling mode. The engine temperature should be > 40° Celsius.

- Operate the brake pedal several times in order to reduce the pressure in the brake booster

If everything in the system is in good working order, at the same time it should be possible to hear the vacuum pump temporarily running up in order to increase the required vacuum in the brake booster or alternatively balance it out.

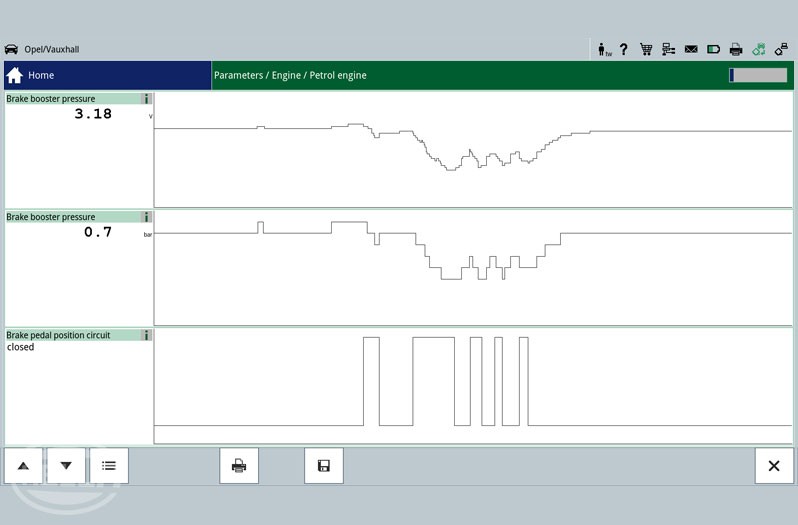

If necessary, another option would be to connect a diagnostic unit so as to show the pressure gradient in the brake booster using the "Parameter" function

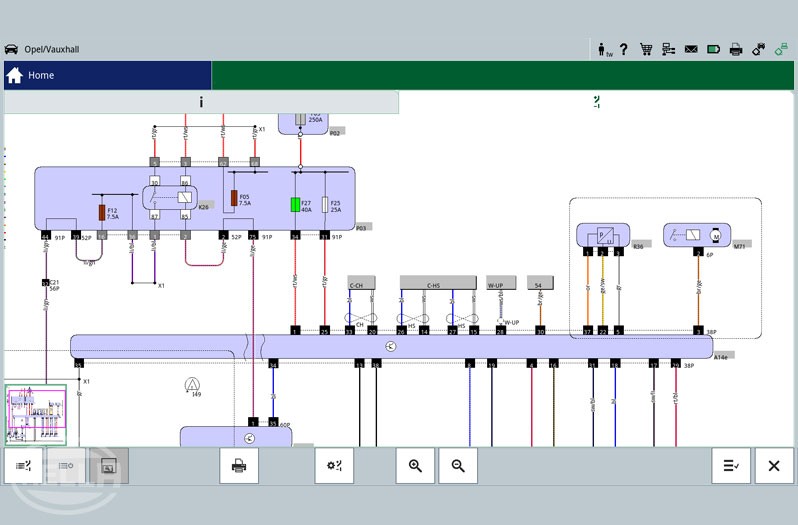

Control unit diagnosis

As part of control unit diagnostics, it is possible to employ the help of various functions and vehicle information as and when needed.

Important

The respective test depth and variety of functions can be set out differently depending on the vehicle manufacturer and is dependent on the relevant system configuration of the control unit.

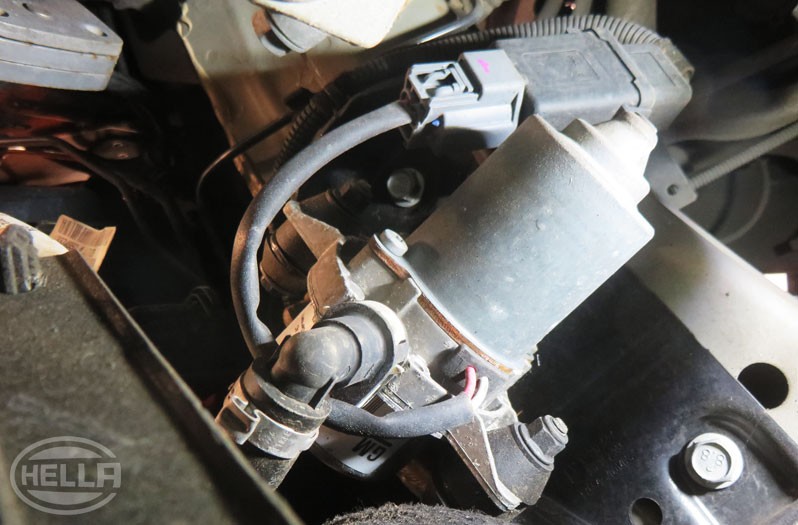

Replacing an electric vacuum pump

Because of the mounting position, removal of the electric vacuum pump is carried out on this vehicle model from the underside and can be completed without the need for any special tools.

Repair notes

When carrying out repairs on the brake system, please pay careful attention to the following information:

- The brake system is a safety system.

- Repair work on brake systems can be carried out exclusively by trained specialists.

- Repair work that is carried out incorrectly can lead to system failure and to severe personal injuries.

- For all repair work performed on the brake system, please observe the safety and assembly instructions provided by the system or vehicle manufacturer in question.

How helpful is this article for you?

Success

Success

Success

Success

Error

Please tell us what you did not like.

Thank you for your feedback!

Wrong Captcha

Something went wrong

You might also be interested in