Media pump - design, function and troubleshooting

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

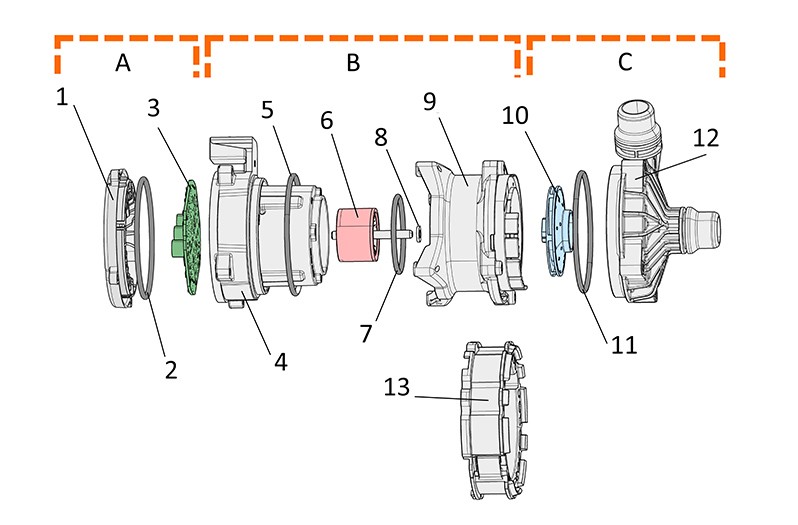

Coolant circulation pump - media pump mp150

Design and function of the HELLA media pump

Blockage detection, dry-running detection

If there is a blockage or no coolant in the pump, the defect is detected by the integrated electronics based on the pump speed and the starting current. If there is no change within a test cycle initiated by the control unit, the pump is switched off and an error entry is generated

Temperature detection

Since the maximum coolant temperature for the MP150e is 90°C, the temperature reduction is designed to maintain the temperature within the specified range. The temperature derating of the pump controls the temperature of the electronics by reducing the current consumption.

If the coolant temperature rises above the maximum value or the temperature sensor on the PCB is damaged, the electronics detect the over temperature error. The pump electronics classify 124°C as an over temperature error and stop the pump in a controlled manner

Voltage and current detection

If overvoltage or undervoltage is detected, the pump goes into idle mode and runs at reduced power to ensure the coolant flow.

If overcurrent is detected, the pump stops to prevent the high currents from damaging the pump.

For both errors, a fault code is stored in the fault memory

Active cooling concept

The active cooling concept ensures improved dissipation of thermal energy within the pump by thermally coupling the printed circuit board and the motor windings to the cooling circuit and optimally placing the current-carrying components to improve temperature distribution on the printed circuit board.

This means that the MP150e can be operated with high electrical current density in the stator windings without overheating and is largely outside the influence of the ambient temperature

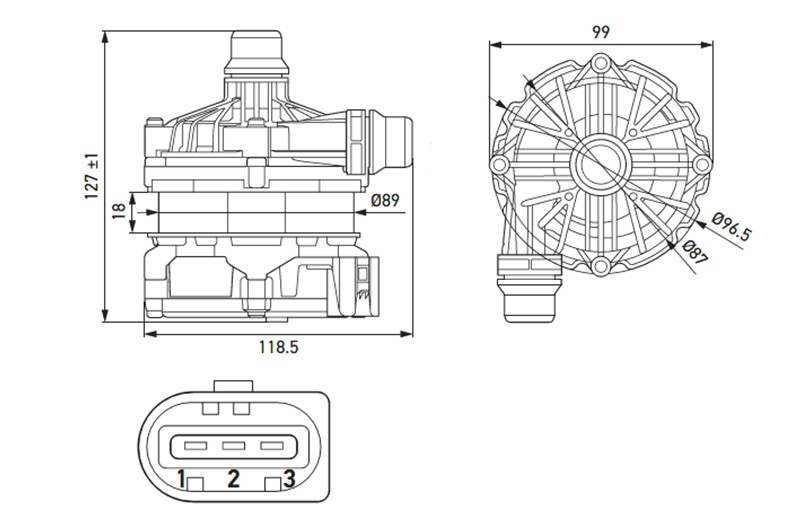

Technical data and dimensions

| Technical data for MP 150 | |

| Rated voltage | 12 Volts |

| Voltage range | 8 - 16 Volts |

| Operating temperature | Coolant -40 °C to +90 °C Ambient range -40°C to +120°C |

| Hydraulic operating point | 3000l/h (Δp = 1.1bar, T_med =50°C, glycol/water mixture 50/50, U = 12 V) |

| Direction of rotation | Right |

| Degree of protection | IP6KX, IPX6K, IPX7, IPX9K |

| Weight | 670 g |

| Lifetime | > 30000 h |

Technical data may vary depending on the design.

Areas of application

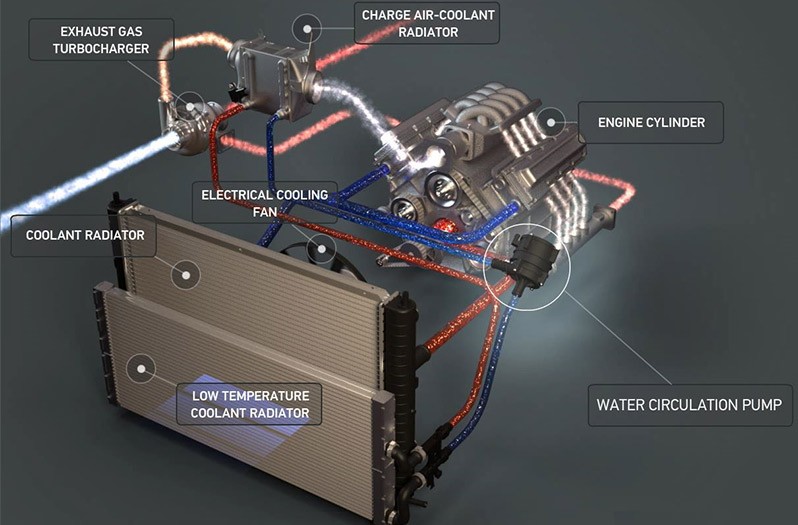

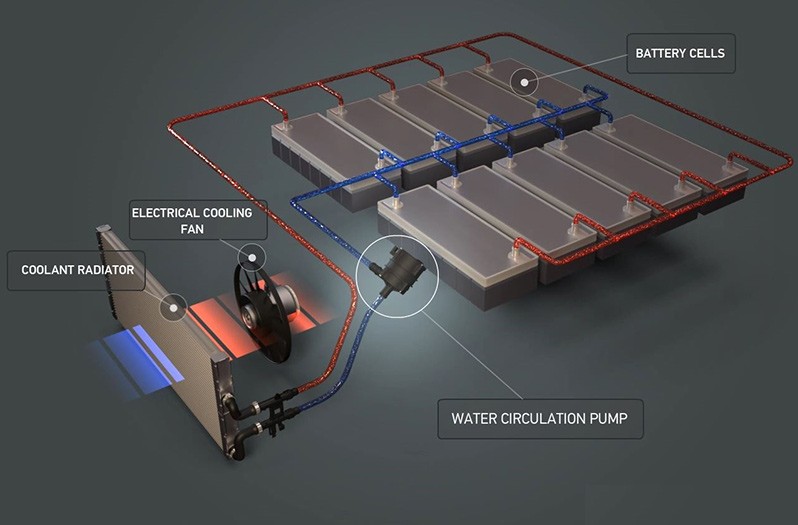

Electric coolant circulation pumps are used in main or auxiliary cooling circuits of vehicles with combustion engines or alternative drives.

Their areas of application are:

- Engine cooling

- Cooling of the exhaust gas recirculation

- Indirect charge air cooling

- Transmission cooling

- Cooling of battery, power electronics or drive in hybrid and electric vehicles

Depending on the drive type (internal combustion engine, hybrid, electric) and the system, one or even several pumps can be installed in the vehicle

System integration in the vehicle

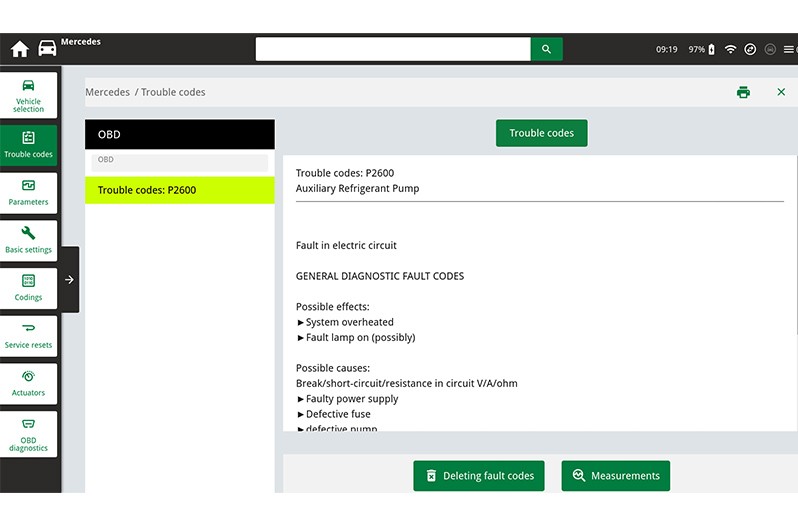

Testing and fault diagnosis

Effects and causes of failures

Severe mechanical strain, contamination, coolant loss and high temperature differences promote wear and can lead to a defect in the coolant circulation pump over time.

Reasons for failures can be:

- External or internal mechanical damage

- Leaks - loss of coolant

- Contamination in the cooling system

- Coolant quality

- Faulty power supply

Important!

A defective MP 150 media pump must be replaced!

Repair is not provided by the manufacturer

Repair and assembly instructions

The cooling system is under pressure.

- There is a risk of injury from leaking coolant.

- Before repairing the cooling system, make sure to bring down the system pressure.

- Wear safety goggles and protective clothing

If the electrical coolant circulation pump is to be replaced as part of the repair, it is imperative that you observe the safety advice and the repair instructions of the product manufacturers and the vehicle manufacturers

Important!

Schematic illustrations, pictures and descriptions serve to explain and illustrate the document text and cannot be used as a basis for vehicle-specific repairs.

The control unit diagnostics have been illustrated using the mega macs 77 diagnostic unit as an example. The respective test depth and variety of functions can be set out differently depending on the vehicle manufacturer and these are dependent on the relevant system configuration of the control unit.

How helpful is this article for you?

Success

Success

Success

Success

Error

Please tell us what you did not like.

Thank you for your feedback!

Wrong Captcha

Something went wrong

You might also be interested in