Car airbag system

Passive safety systems are responsible for ensuring that passengers are protected to the greatest possible extent in the event of an accident. A wide variety of airbags are available nowadays, and they are now provided as standard in all vehicle classes. This page explains which components can be found in a modern restraint system and how airbags and seat belt tensioners protect drivers against injury in an emergency. You will also find important information on troubleshooting passive safety systems.

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

- 1. Basics

- 2. Components

- 3. Design

- 4. Troubleshooting

Car airbag system SRS

Airbag function

Information acquired from a range of crash tests is saved in modern control units. This information enables an accident to be classified according to the "crash severity".

In this context, a distinction is made between the following:

- Crash severity 0 = minor accident; no airbags are deployed

- Crash severity 1 = moderate accident; airbags may be deployed in the first stage

- Crash severity 2 = serious accident; airbags are deployed in the first stage

- Crash severity 3 = very serious accident; airbags are deployed in the first and second stages

Alongside the crash severity, the control unit also takes into account information about the direction of the accident (the application of force), for example 0° or 30°, and the type of accident in order to determine the deployment strategy. In addition, it considers whether or not the occupants are wearing their seat belts.

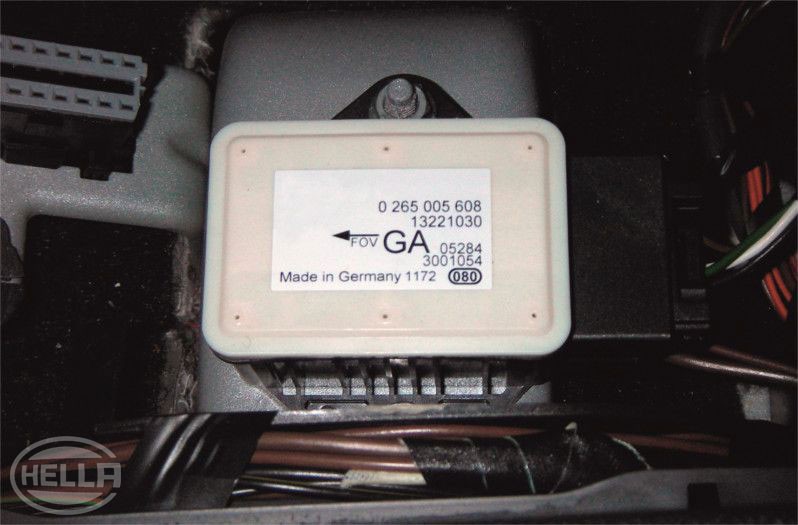

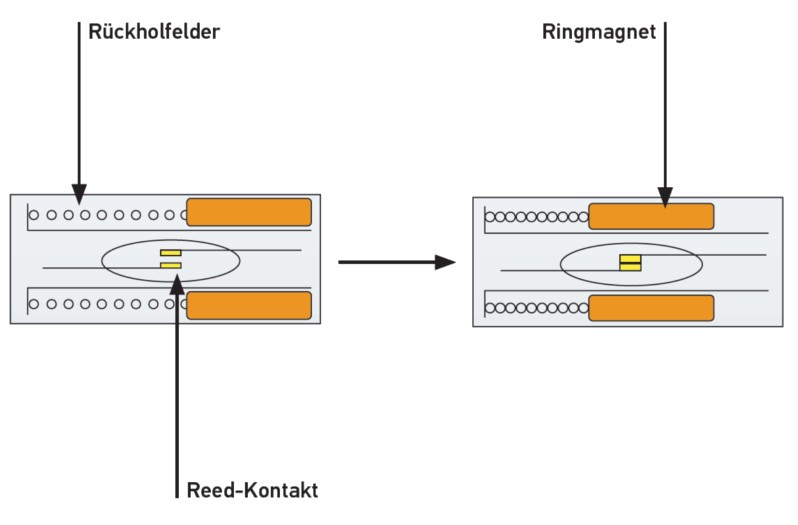

Another expansion option for movement sensors is to use a silicon mass. If force is applied, the silicon mass in the sensor moves. Due to the way in which the mass is suspended in the sensor, this changes the electrical capacitance, which serves as information for the control unit.

Thanks to the speed at which they can record information, these sensors are used to supply information to the control unit as quickly as possible in the event of a side impact.

Pressure sensors are also used. They are installed in the doors and respond to changes in pressure inside the doors in the event of an accident. When working on vehicles that use these pressure sensors, it is essential to properly refit the door sealing foils following their removal. If the door sealing foil has been incorrectly fitted and this results in pressure loss during an accident, the function of the pressure sensors may be impaired.

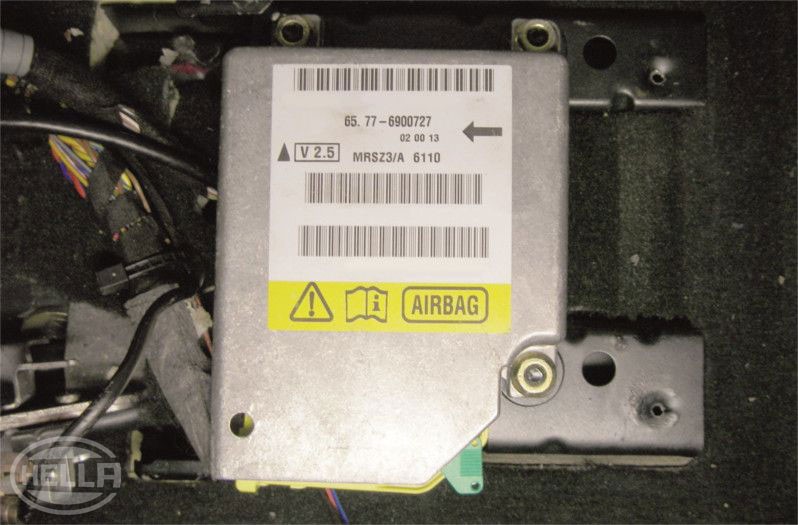

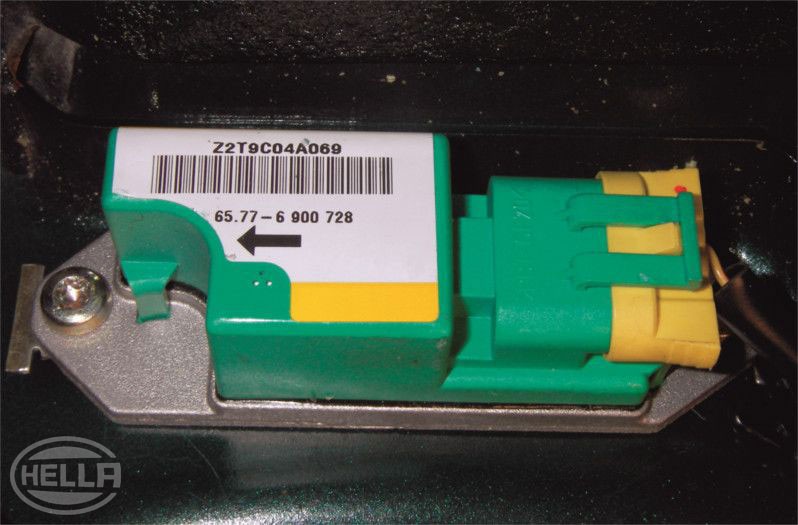

When mounting the crash sensors, always observe the installation direction, which is indicated by an arrow on the sensor. The deployment threshold is an acceleration of approx. 3 – 5 g. For safety reasons, in order to avoid the airbag(s) being deployed unintentionally, two sensors that operate independently from one another must always send the information to deploy the airbag(s). The safing sensor is used as a safety sensor.

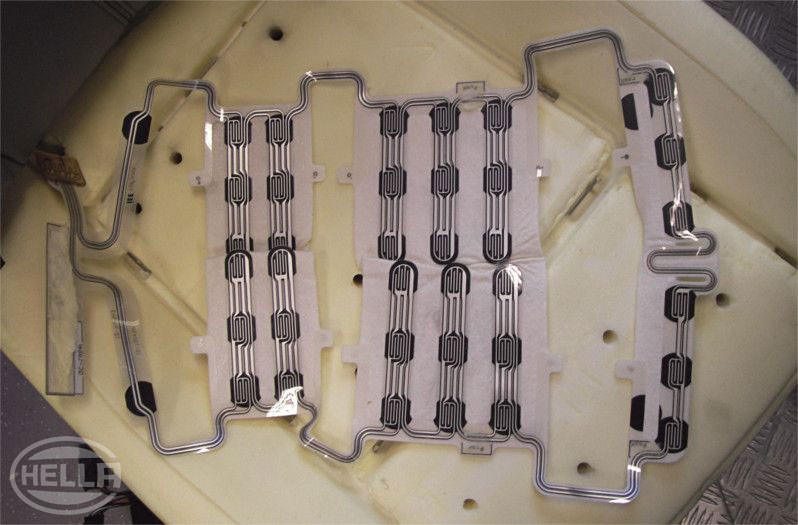

Airbag design

Which propellant is used depends on the size of the airbag and the required opening speed. The chemical reaction that takes place following the firing causes temperatures of 700°C in the combustion chamber. The resulting gas flows through a filter screen at a pressure of approx. 120 bar. In the process, it is cooled down to reduce the temperature at the outlet to less than 80°C in order to protect the occupants. The noise produced is similar to a gunshot. It takes around 30 ms for the airbag to fully inflate. Newer systems use two-stage gas generators. Depending on the severity of the accident, the control unit fires the two firing pellets one after the other. The shorter the interval between the firings, the faster the airbag will inflate. In any case, both gas generators are always fired in order to safely rescue the occupants from the vehicle.

Hybrid generators are used for the front passenger airbag or side airbag. These types of generators also use a second gas source in addition to the burnup gas. A pressure vessel contains a gas mixture of 96% argon and 4% helium at a pressure of approx. 220 bar. The pressure vessel is sealed by a diaphragm. If the airbag is deployed, the propellant moves a piston that punctures the membrane and allows the gas to flow out. The gas produced when the propellant burns mixes with the gas in the pressure vessel. The outlet temperature is around 56°C in this case. The front passenger airbag has a volume of around 140 l and fully inflates in around 35 ms.

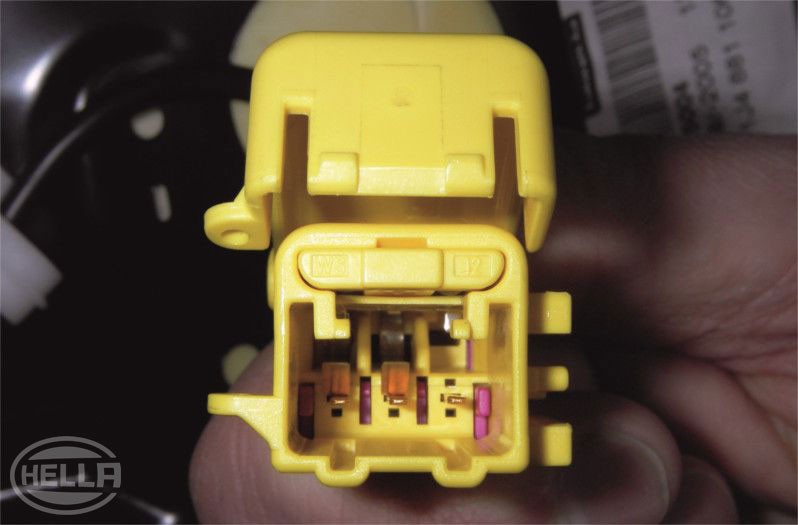

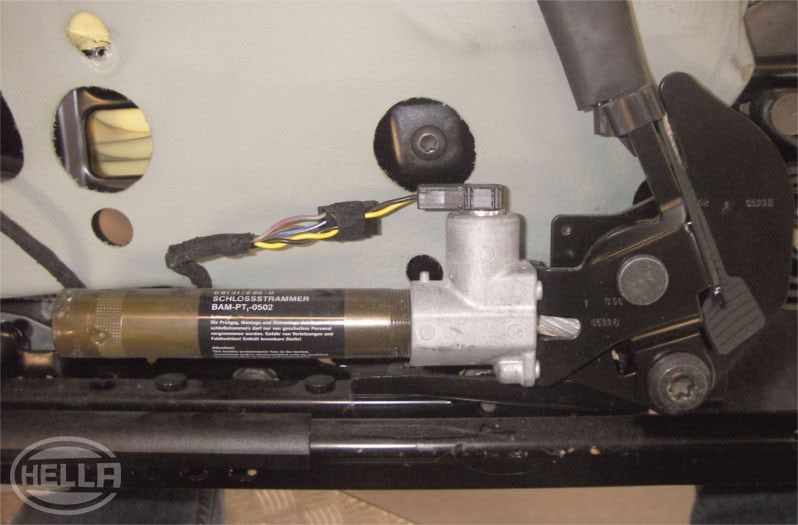

Belt force limiter

Belt force limiters are adaptive belt machines that use a gas generator, like in an airbag, to switch between a high and low level of force.

Thanks to the optimal coordination between the seat belt tensioner and airbag, the kinetic energy of the occupants is slowly dissipated over the course of the impact, which reduces the loads.

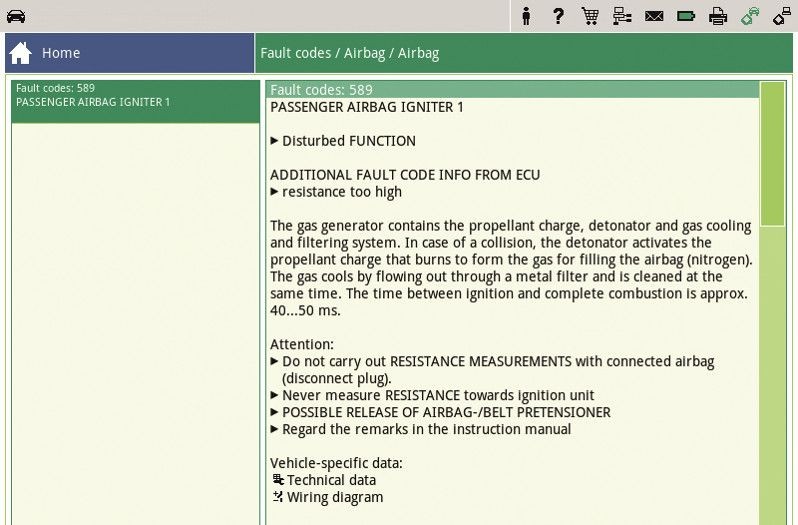

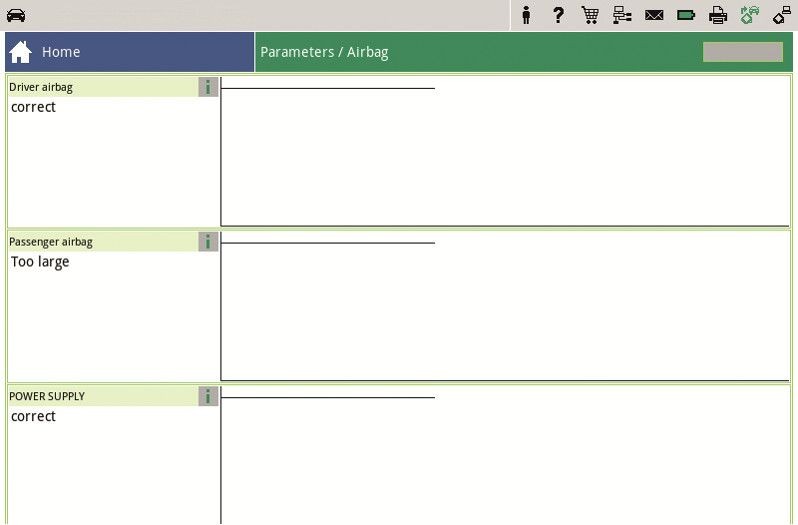

Testing and diagnostics on airbag systems

How helpful is this article for you?

Success

Success

Success

Success

Error

Please tell us what you did not like.

Thank you for your feedback!

Wrong Captcha

Something went wrong

You might also be interested in