Preparation

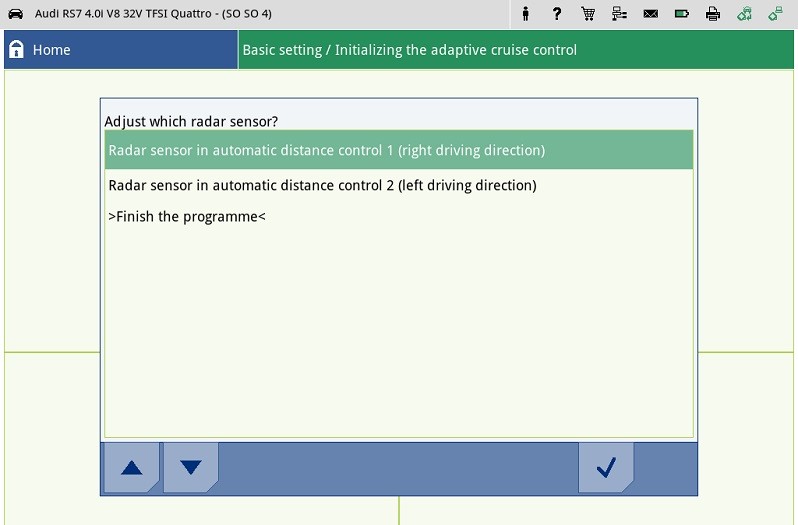

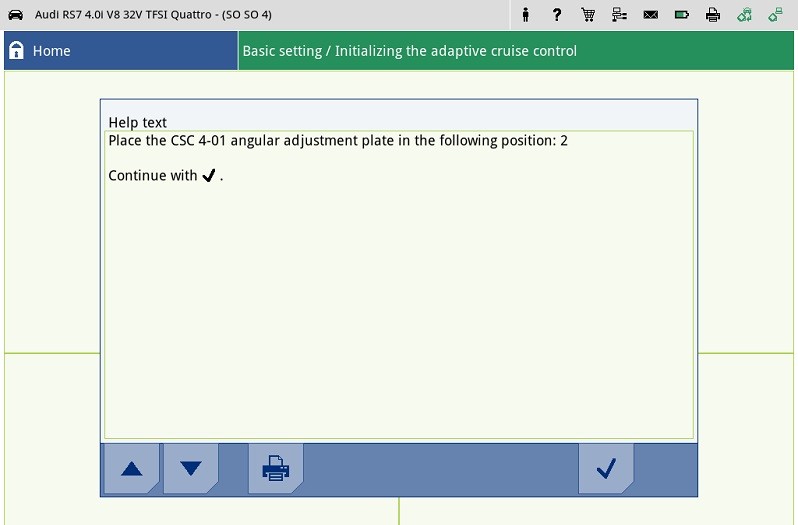

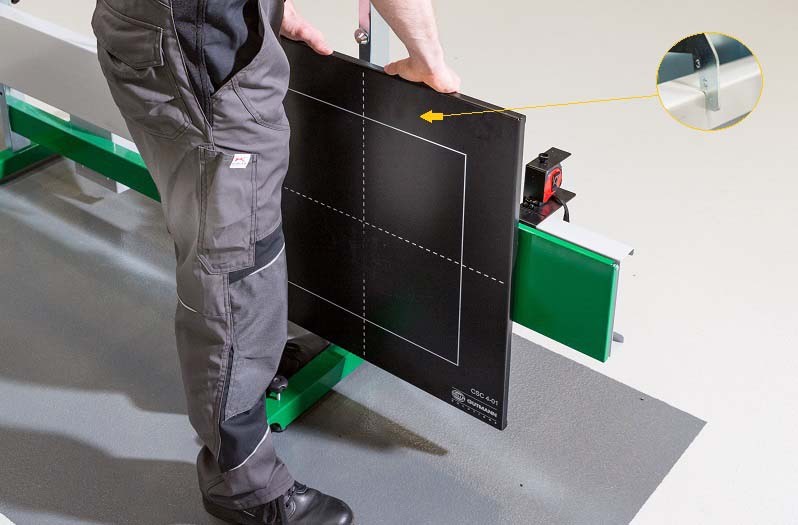

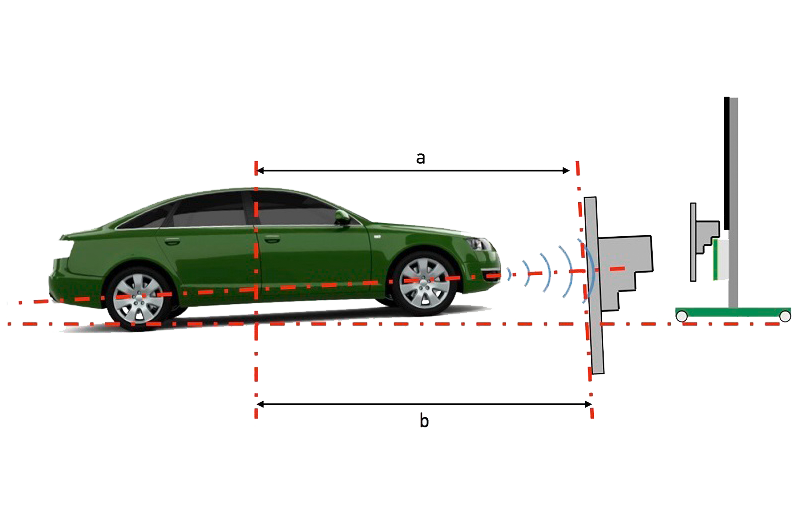

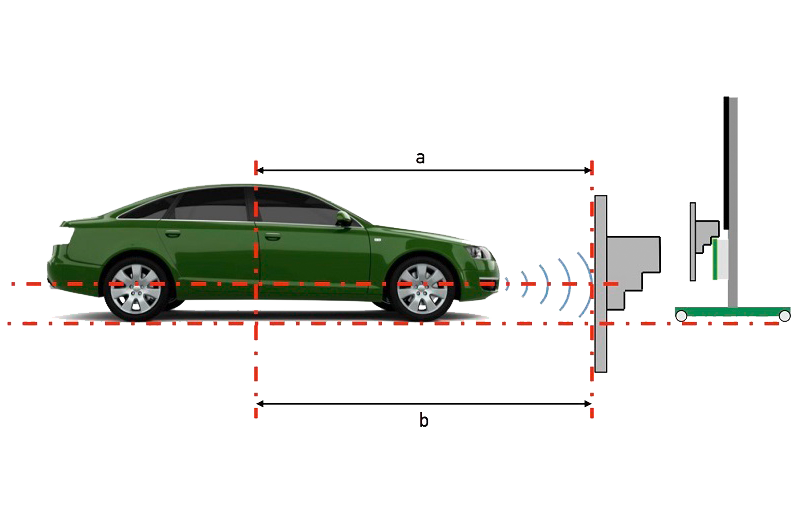

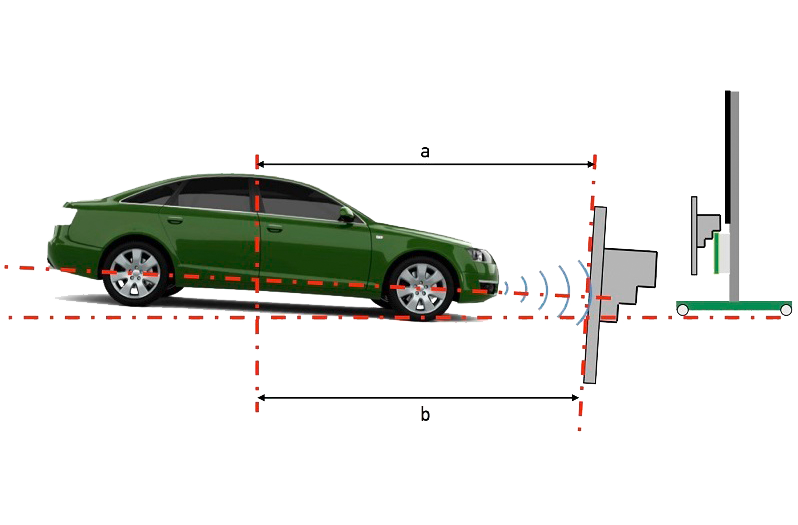

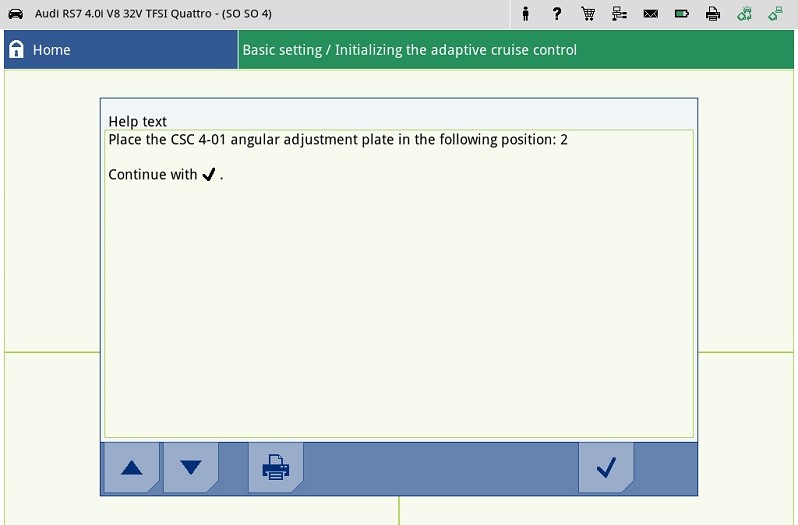

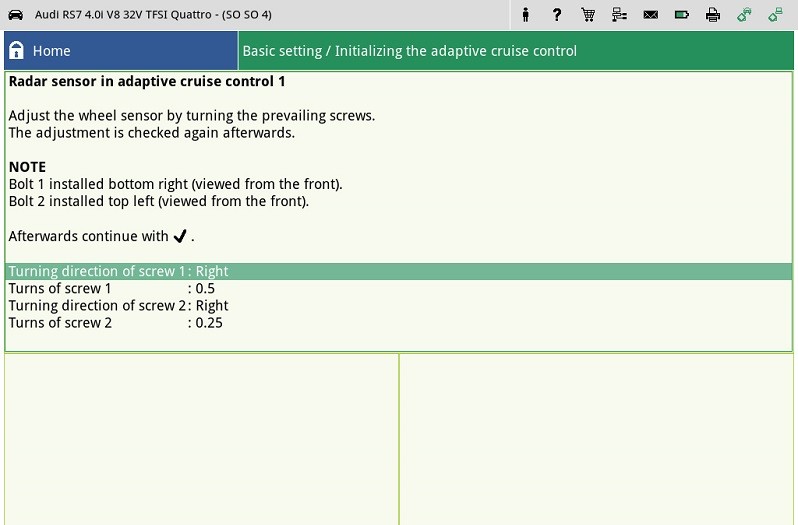

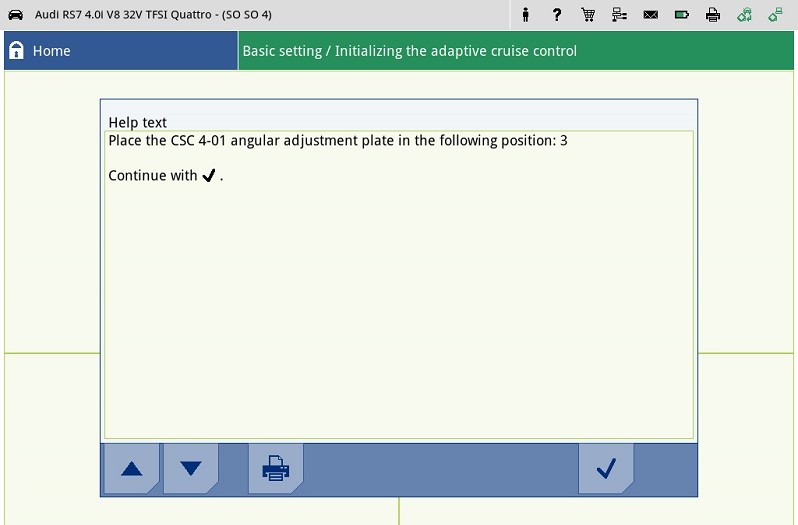

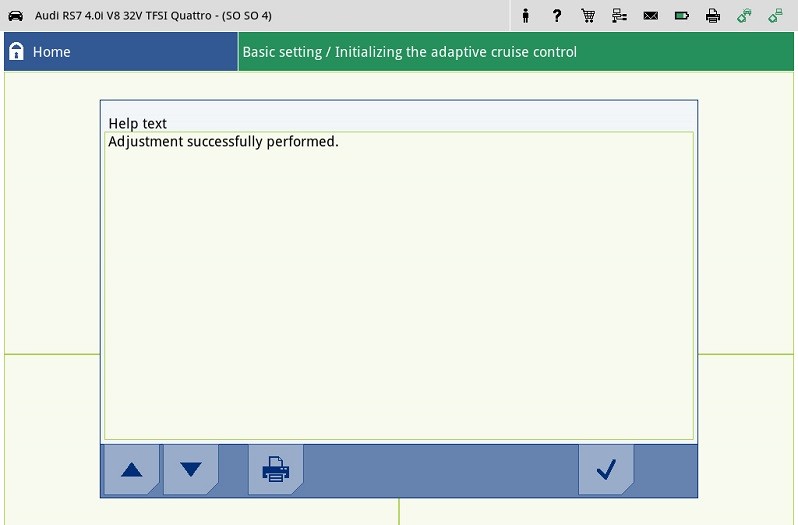

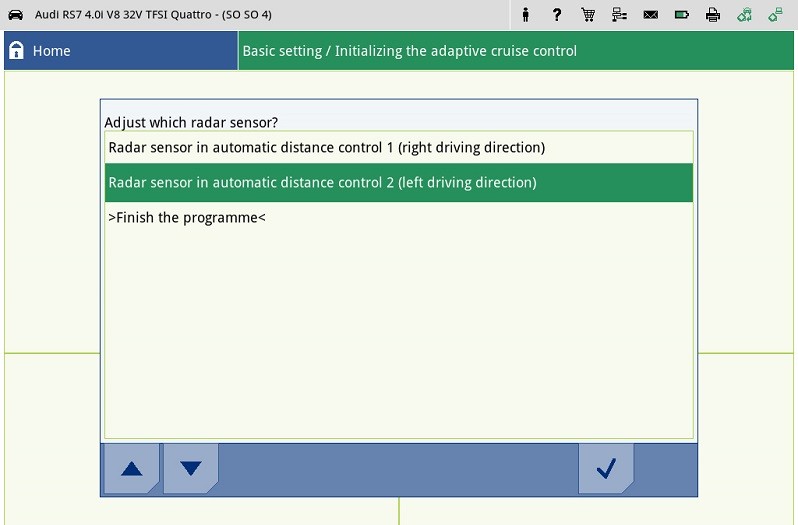

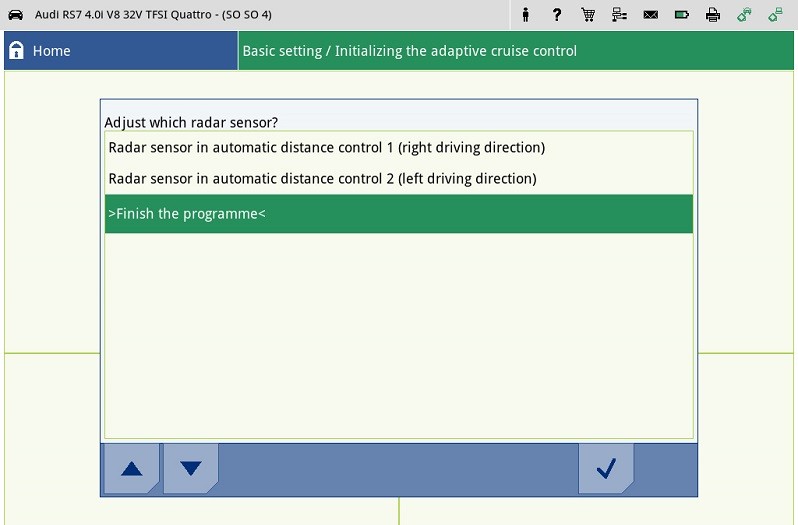

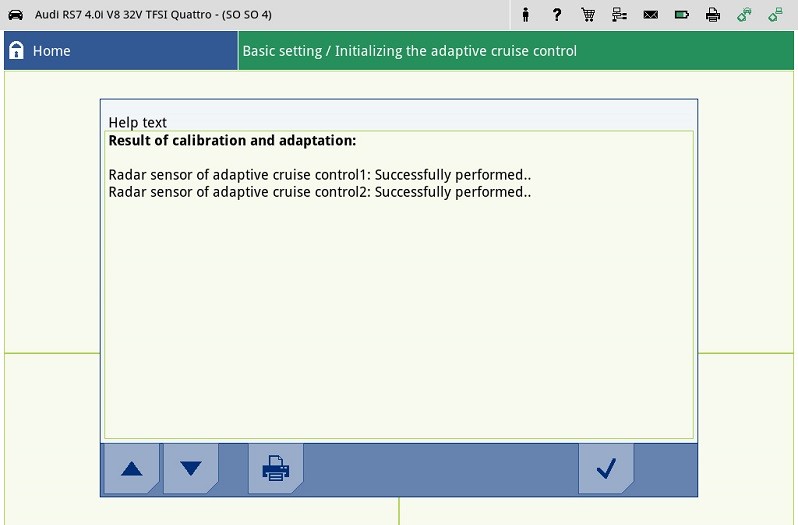

The vehicle is placed on a set-up testing station. In addition to the CSC Tool with radar attachment, the mechanic needs a connected battery charger as well as the mega macs diagnostic unit. From the beginning, the mega macs will guide you through the process.