Activated charcoal canister

The activated charcoal canister protects the environment against unburnt fuel vapours. This page explains how the system works, what could cause a fault, and how malfunctions affect the running of the engine. You will also find valuable practical tips for troubleshooting in connection with the activated charcoal canister

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

- 1. Basics

- 2. Function

- 3. Symptoms

- 4. Cause of failure

- 5. Troubleshooting

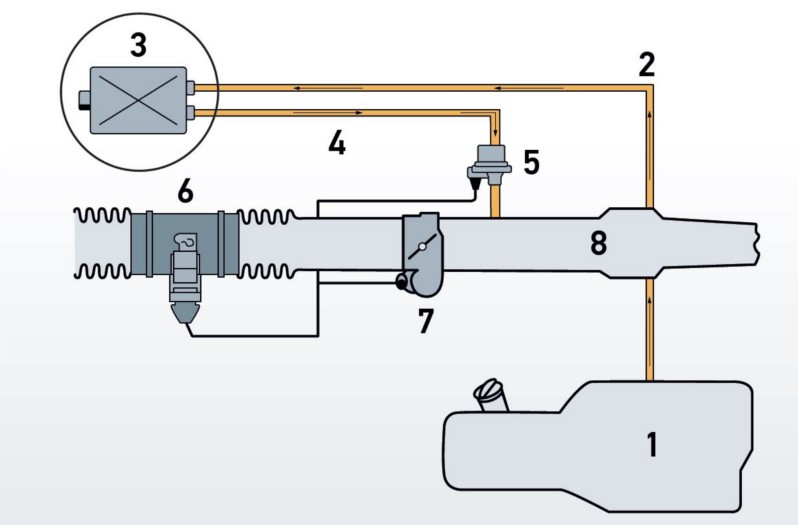

Basic principles of the activated charcoal canister

Functional principle of the activated charcoal canister

Activated charcoal canister faulty

Fault symptoms in the event of failure:

- E.g. fault code P0441: Tank bleeder system throughput faulty

- Engine does not run smoothly

- Smell of gasoline due to escaping fuel vapors

Causes of a faulty activated charcoal canister

Causes of a failure:

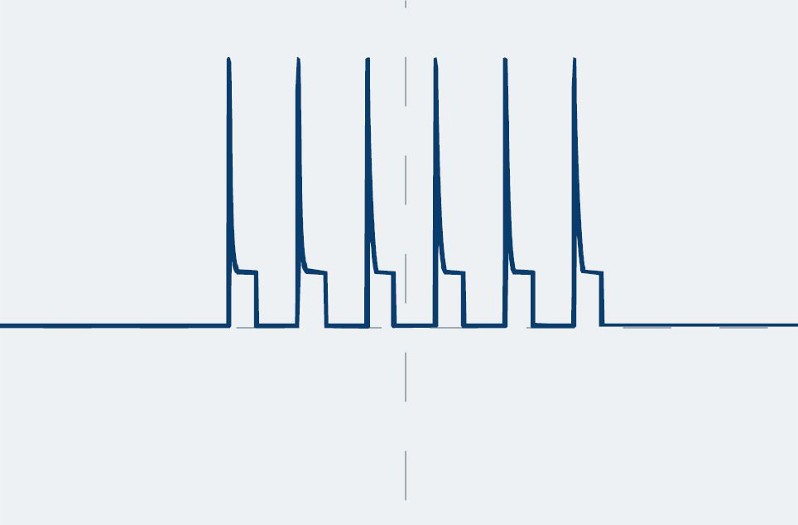

- No control by the control unit

- Faulty timed valve

- Mechanical damage (accident)

- Faulty lines

Checking the activated charcoal canister

How helpful is this article for you?

Success

Success

Success

Success

Error

Please tell us what you did not like.

Thank you for your feedback!

Wrong Captcha

Something went wrong

You might also be interested in