Defective water pump

The coolant pump ensures circulation of coolant in coolant circuit and that engine heat is reliably transmitted to ambient air. At the same time, it is the most strained component of cooling system. Learn on this page how coolant pumps work, what might cause damages and what to take into account during replacement.

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

- 1. Function

- 2. Symptoms

- 3. Damages

- 4. Video

Water pump

Coolant pumps, also often referred to as water pumps, are mostly powered mechanically via a sprocket or V-ripped belt, and transport the coolant through the engine's coolant circuit . The pumps can be found either directly flanged to the engine or installed at a distance. The designs are very different.

Coolant pumps must withstand enormous temperature variations (- 40°C to ca. +120°C). Changing rotational speeds (500 - 8000 rpm) and pressures of up to 3 bars require great bearing and sealing resistance.

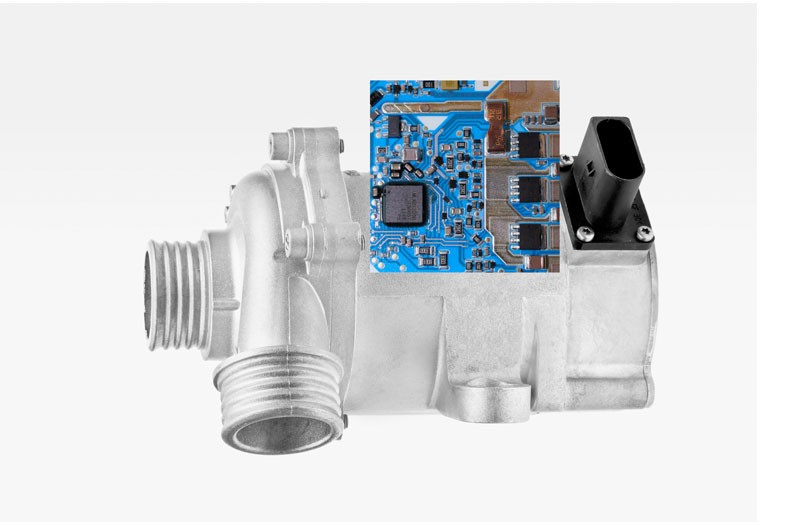

For saving fuel, more electrically powered and electronically controlled coolant pumps will be used in the future.

An additional advantage consists in the ability to install electric cooling pumps individually and outside of the engine. They are relatively light and maintenance-free, thanks to the brushless installation. At an operating voltage of 12-360 volts, it currently reaches outputs of 15 to 1000 watts. Coolants reduce the temperature of the coolant pump's electric motor. A pulse width-modulated (PWM) signal control makes flexible adjustment possible. This, in turn, enables controlling the transported volume according to the actual needs and independent of engine rotation, thus allowing keeping the cooling temperature constant as required by the respective system. Thanks to their inclusion in the wiring system electronics, electric coolant pumps can also be diagnosed. Depending on the drive type (internal combustion engine, hybrid, electric) and the system, one or even several pumps can be installed in the vehicle.

Electrical coolant pumps have many areas of application:

- Engine cooling

- Charge air cooling

- Cooling of the exhaust gas recirculation

- Drive and battery cooling in hybrid and electric vehicles

- Transmission cooling

- Cooling of diverse power take-offs

Defective water pump

Possible damage symptoms when defective water pump

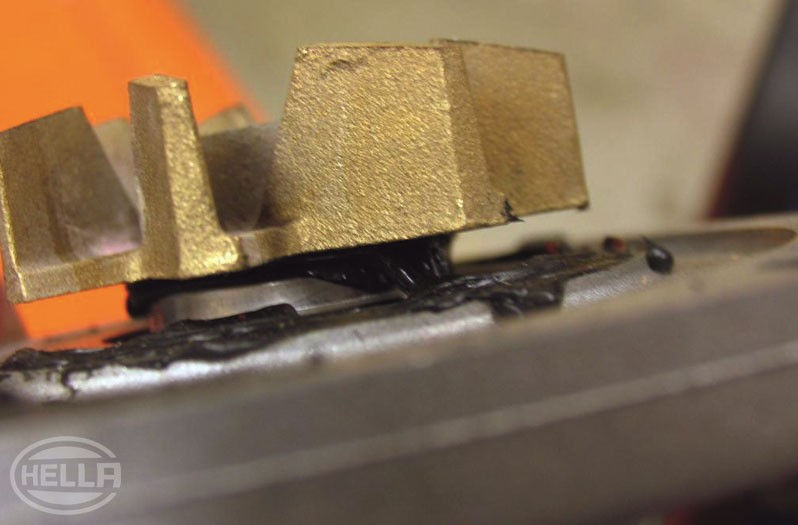

Broken water pump bearing (bearing cage):

- Strong vibrations due to defective

Visco clutch

Replacing water pump

Assembly tips

When replacing the coolant pump, always note the instructions of the product package insert and special installation requirements by the vehicle manufacturer. If the cooling system is contaminated, rinse it.

The cooling system should only be filled with coolants matching the vehicle manufacturer's specifications. Fill and/or ventilate the system according to vehicle manufacturer specifications. A wrong installation can lead to engine overheating , belt drive damage and/or engine damage.

Information on the use, specifications and change intervals of coolants is situated in the respective " Coolant " technical information.

How helpful is this article for you?

Success

Success

Success

Success

Error

Please tell us what you did not like.

Thank you for your feedback!

Wrong Captcha

Something went wrong

You might also be interested in: