Vehicle type:

Motor vehicles, multi-lane, except agricultural or forestry

tractors and working machines, or similar motor vehicles | Setting |

| Headlamps for low beam | Fog lamps |

| 1.1 | EEC (EC) / ECE as a basis for testing | Am Fahrzeug angebendes Einstellmaß | 2.0 % |

| 1.1.1 | Motor vehicles with lighting fixture according to 76 / 756 / EEC or with approval according to ECE-R 48 |

| 1.2 | StVZO (Road Traffic Act) as a basis for testing |

| 1.2.1 | Motor vehicles with initial registration as from 01/01/1990. Headlamps not higher than 1,200 mm above the road1) |

| 1.2.2 | Motor vehicles with initial registration up to 12/31/1989. Headlamps not higher than 1,400 mm above the road1) and motor vehicles with initial registration as from 01/01/1990. Headlamps higher than 1,200 mm but not higher than 1,400 mm above the road1) | 1.2 % | 2.0 % |

| a) | Passenger cars (also combination motor vehicles) | 1.2 % | 2.0 % |

| b) | Motor vehicles with level-regulating suspension or automatic tilt compensation of the light beam2) | 1.0 % | 2.0 % |

| c) | Trucks with loading area at the front |

| d) | Trucks with loading area at the back, except motor vehicles as per 1.2.2 b) | 3.0 % | 4.0 % |

| e) | Truck tractor except motor vehicles as per 1.2.2 b) |

| f) | Buses except motor vehicles as per 1.2.2 b) |

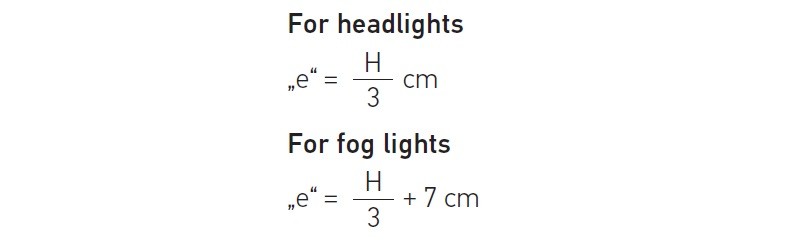

| 1.2.3 | Motor vehicles with headlamps H ≤ 1,400 mm1) | H/3 | (H/3 + 7) |

| 2.0 | Motor cycles and similar motor vehicles |

| 2.1 | 93 / 92 / EEC as a basis for testing | | |

| a) | 2-wheel mopeds | No requirements |

| b) | 3-wheel scooters and 4-wheel light vehicles | | |

| c) | Motorcycles without/with sidecar | 0.5 to 2.5% | 2.0 % |

| d) | 3-wheel scooters | | |

| 2.2 | ECE-R 53 as a basis for testing | Setting indicated on the vehicle | 2.0 % |

| 2.3 | StVZO (Road Traffic Act) as a basis for testing | 1.0 % | 2.0 % |

| 3.0 | Agricultural or forestry tractors and working machines, or similar motor vehicles |

| 3.1 | EEC (EC) / ECE as a basis for testing | | |

| a) | Headlamp height: 500 mm < h ≤ 1,200 mm | 0.5 to 4.0% | 2.0% |

| b) | Headlamp height: 1,200 mm < h ≤ 1,500 mm | 0.5 to 6.0% | 2.0% |

| c) | Additional headlamps (on tractors equipped for front structures) H ≤ 2,800 mm | H/3 | |

| 3.2 | StVZO (Road Traffic Act) as a basis for testing | | |

| a) | Single-axle tractors or working machines with permanent low beam headlamps which indicate the required inclination of the light beam center | 2 x N | 2.0 % |

| b) | Multi-axle tractors or working machines | 1.0 % | 2.0 % |