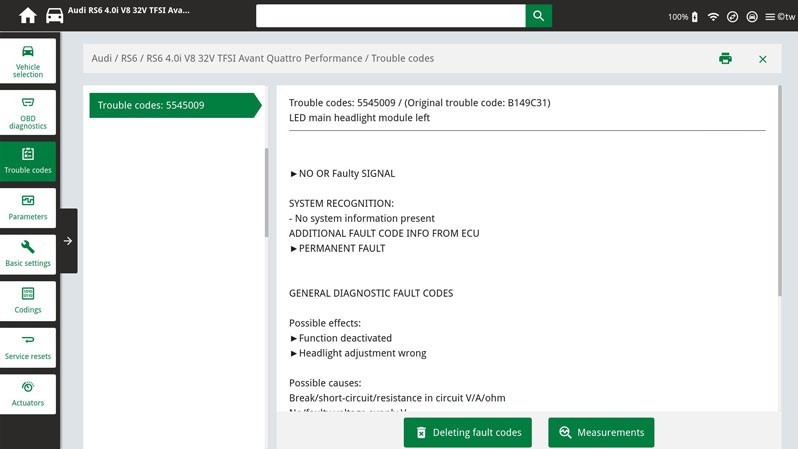

Vehicles with Adaptive Cruise Control (ACC), Night Vision System or Perimeter Camera

Important: If the bumper is removed and reinstalled as part of the repair or changes are made to the radiator grille, a recalibration of the camera for the night vision system, an adjustment of the distance control or a

recalibration of the surroundings camera

is absolutely necessary!

In this context, please observe the repair instructions and safety instructions of the respective system or vehicle manufacturer!

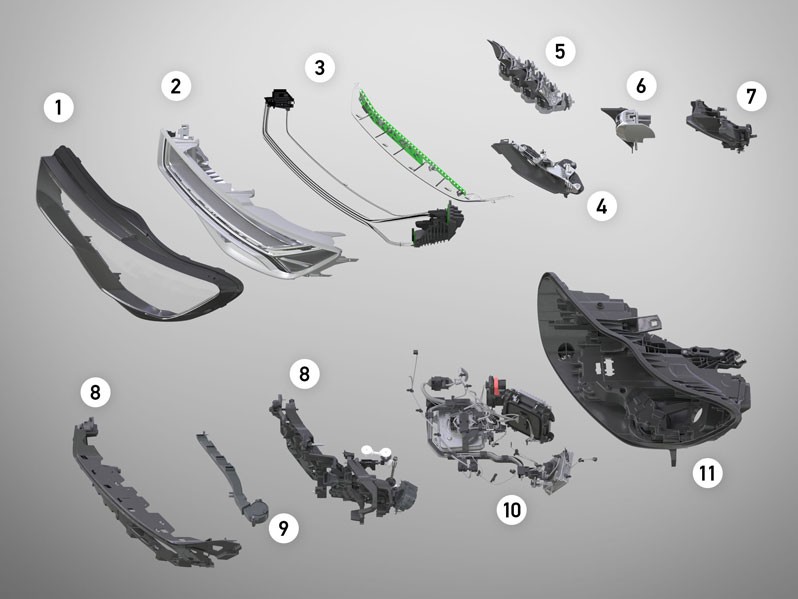

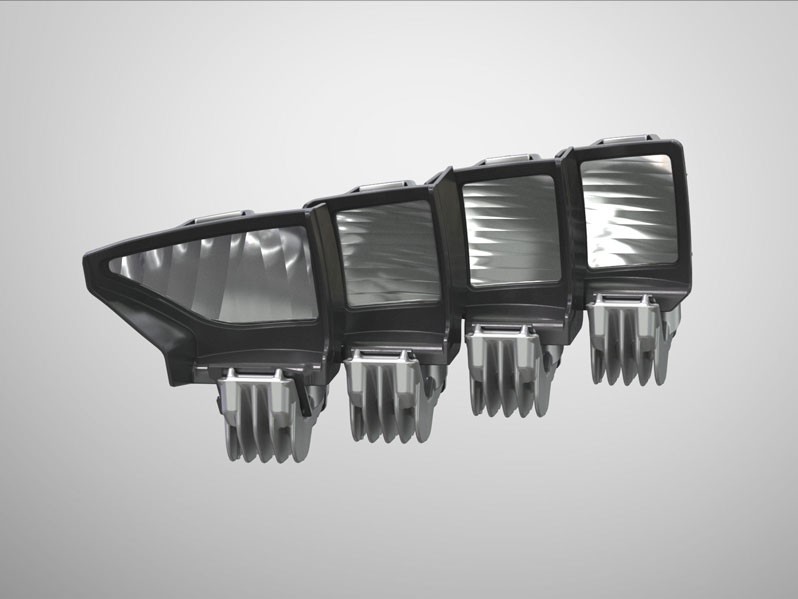

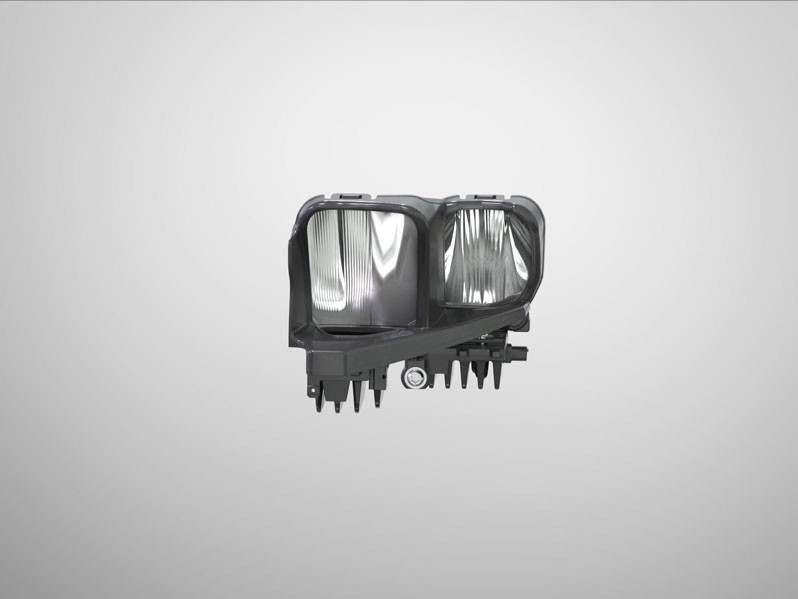

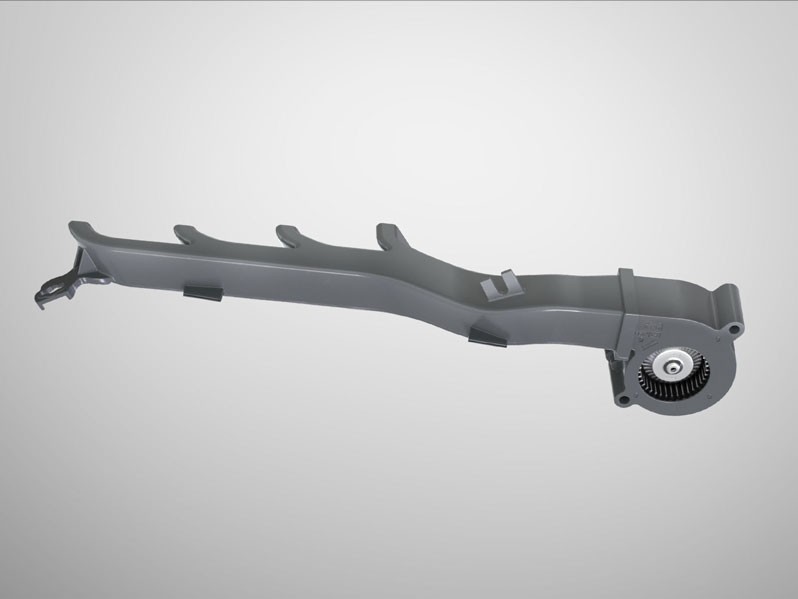

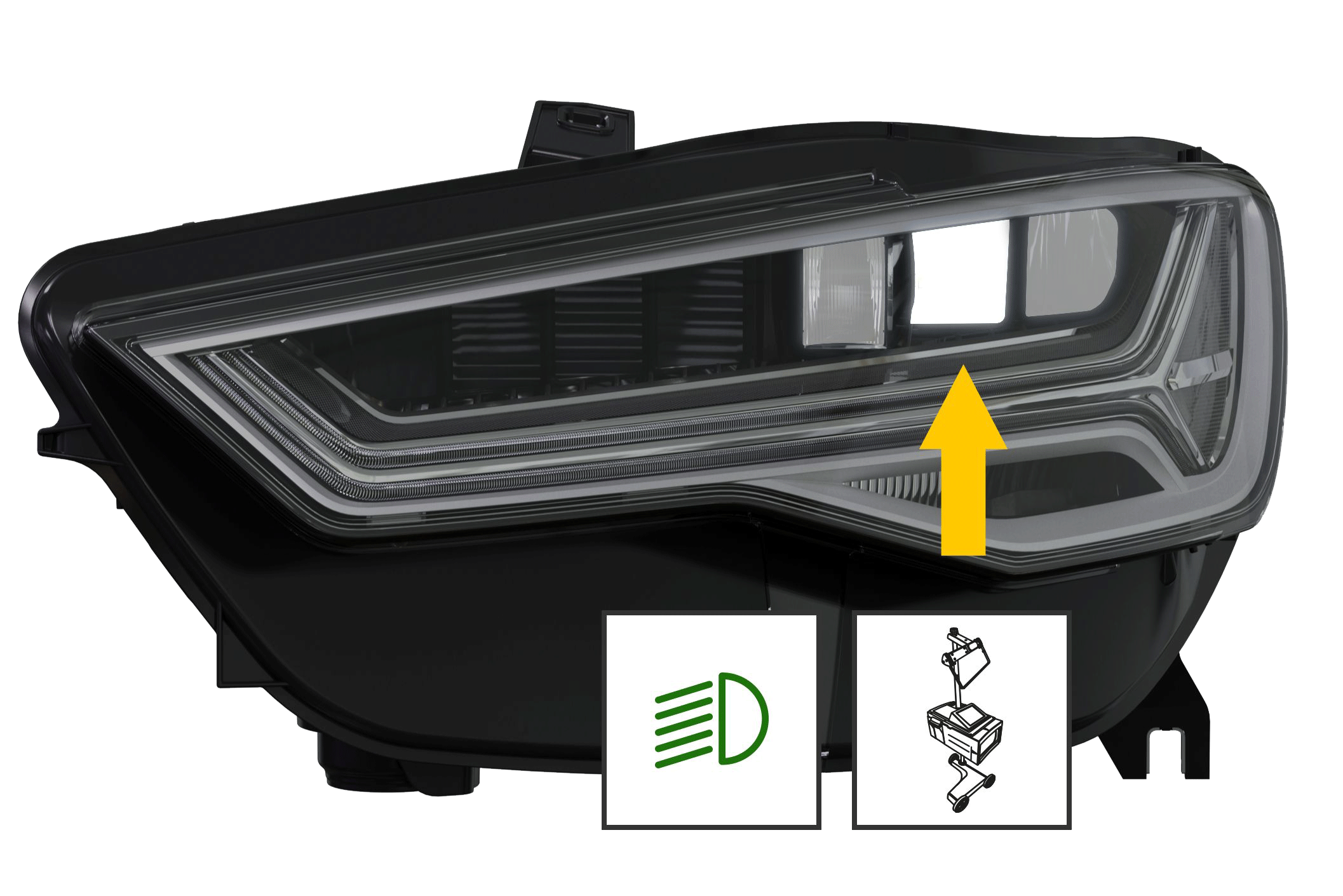

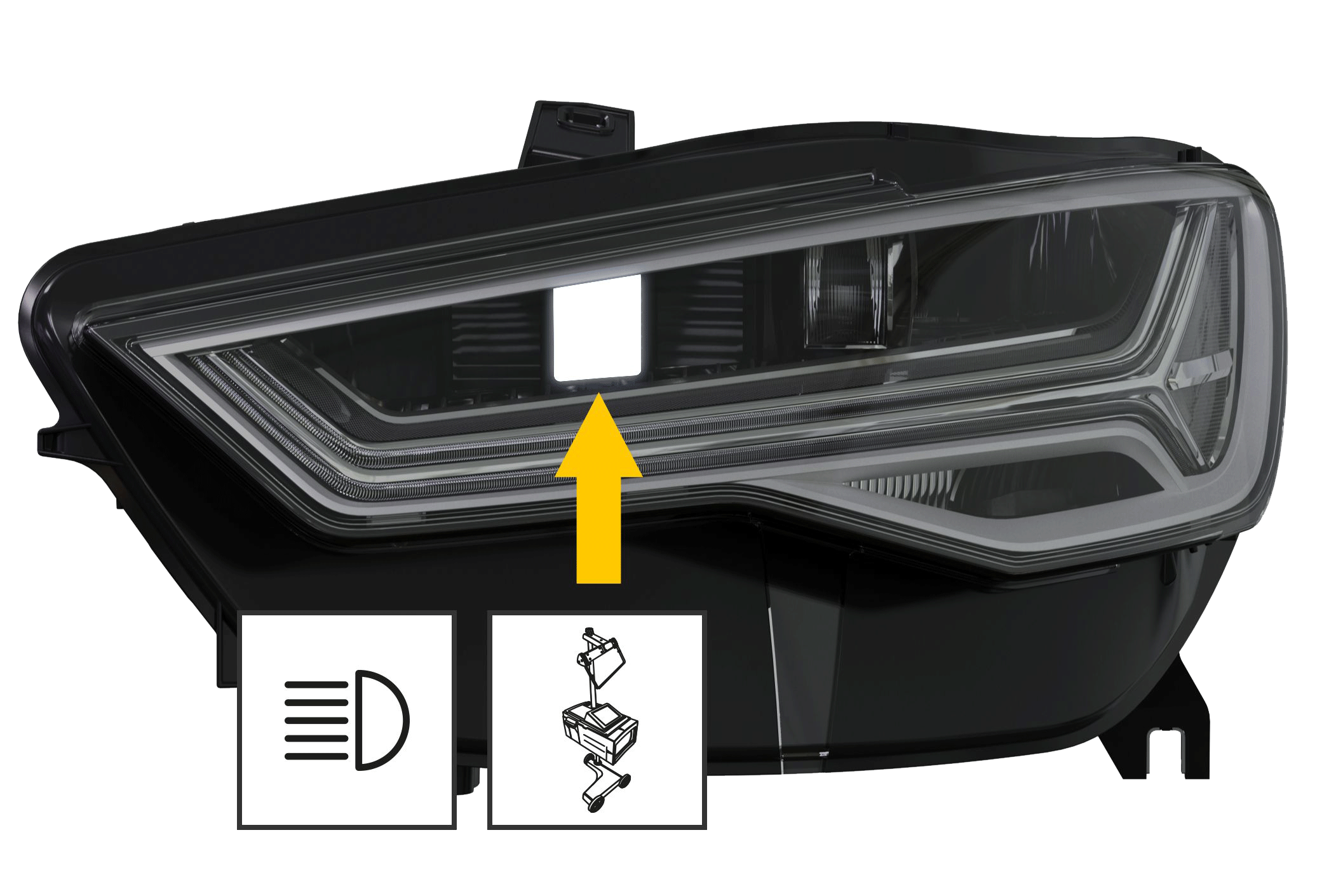

When replacing electronic components in the headlamp, ensure the greatest possible cleanliness.

In addition, the measures for protection against electrostatic discharge (ESD) must be observed.

Repair work on the lighting system in the motor vehicle may only be carried out by trained specialist personnel. Improperly carried out repairs can lead to system failure and, in the worst case, personal injury.