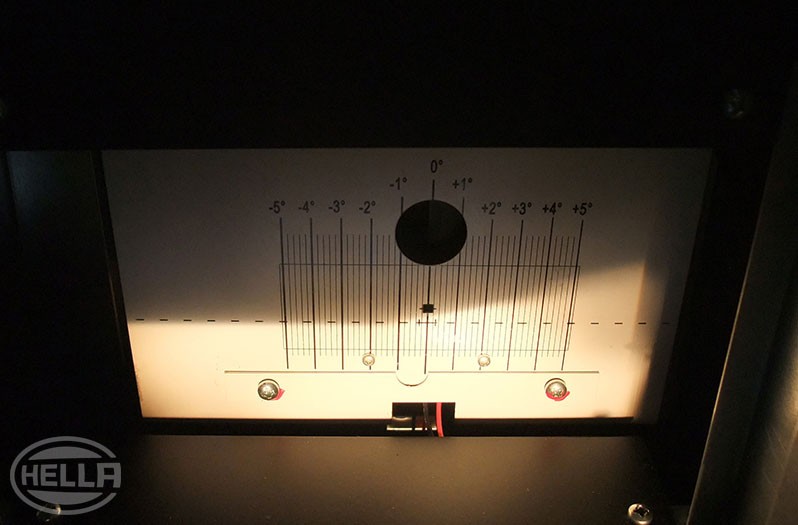

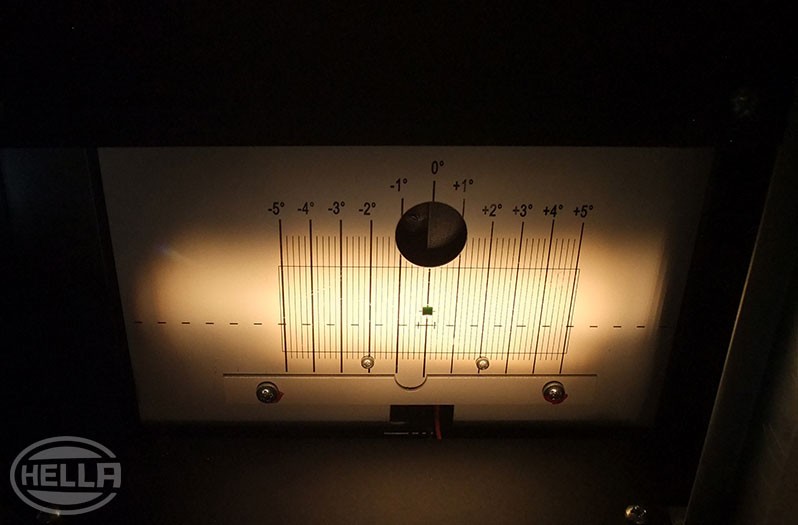

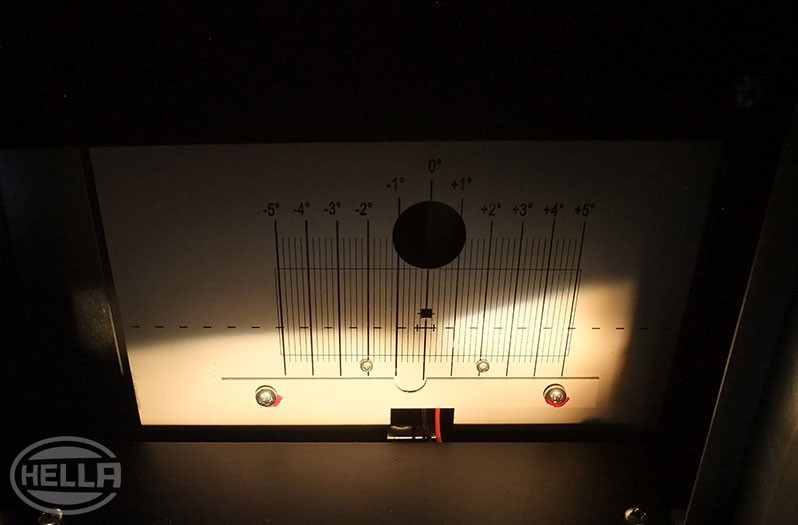

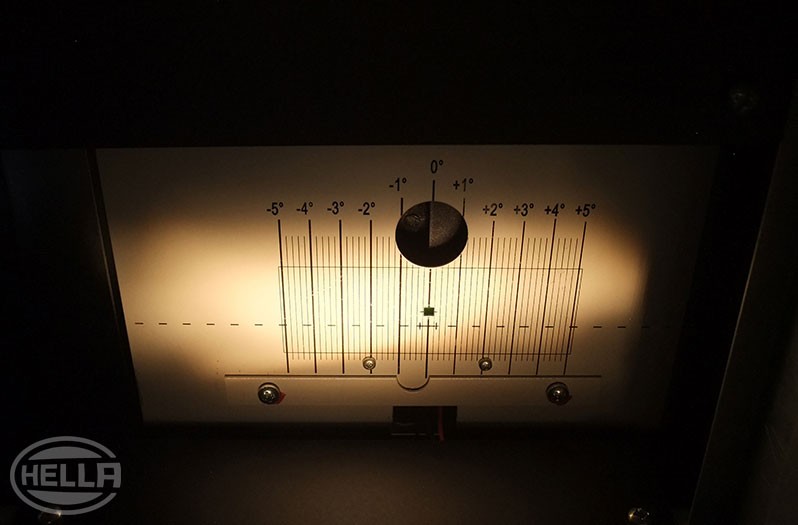

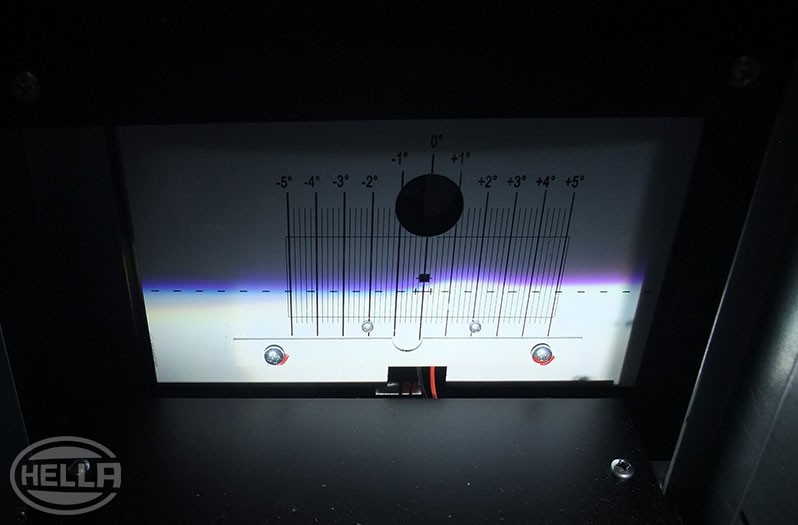

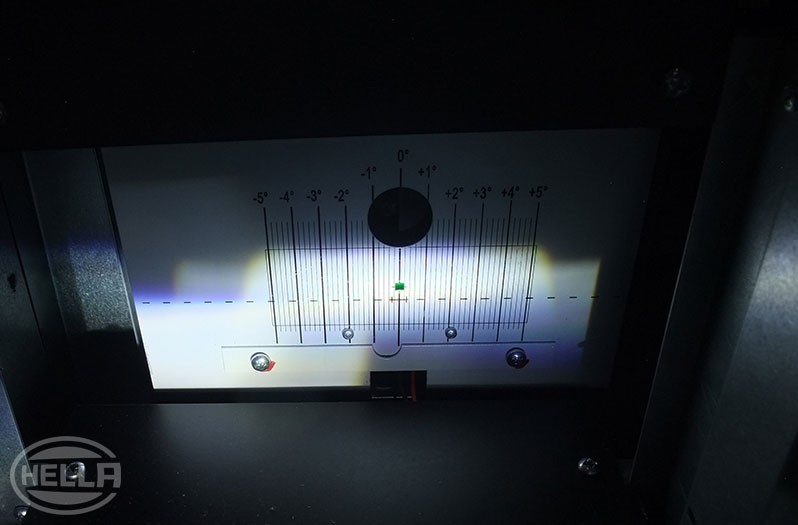

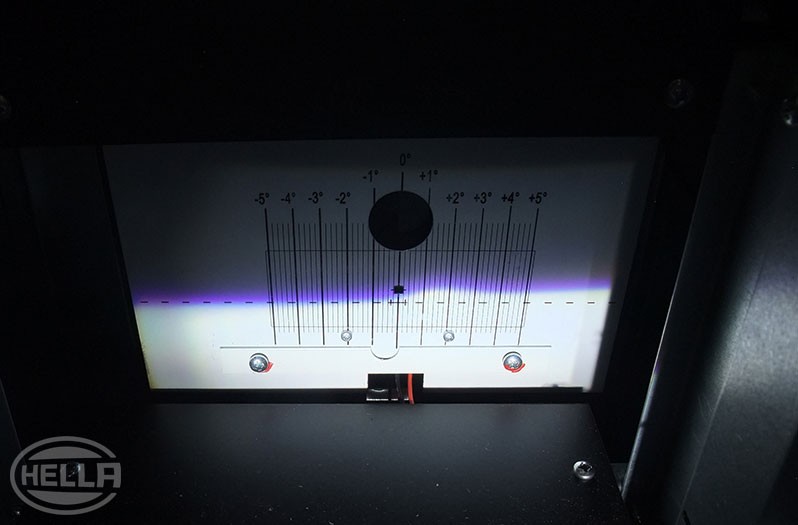

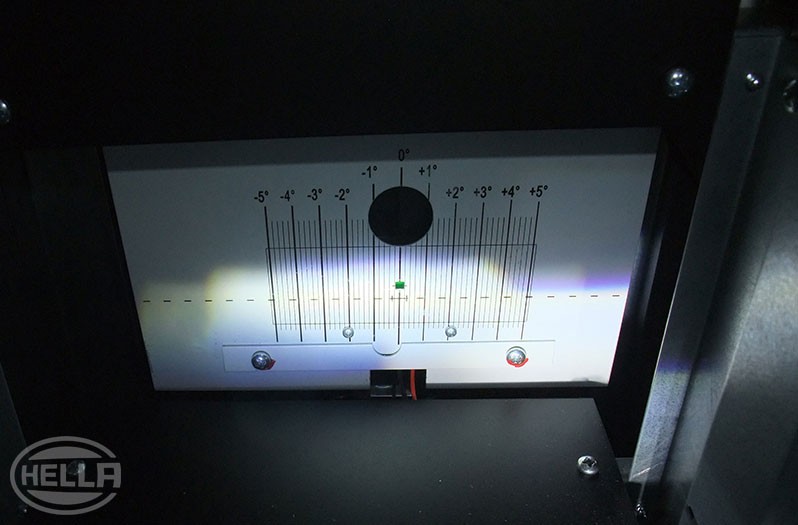

Analogue beamsetter

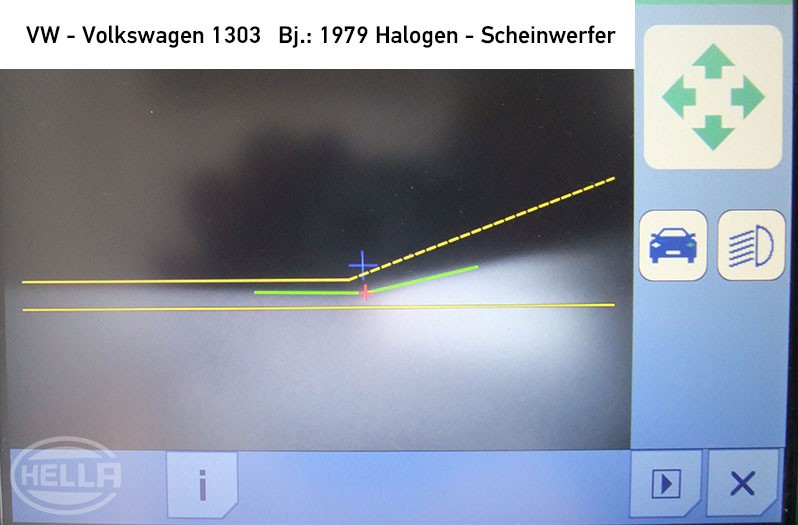

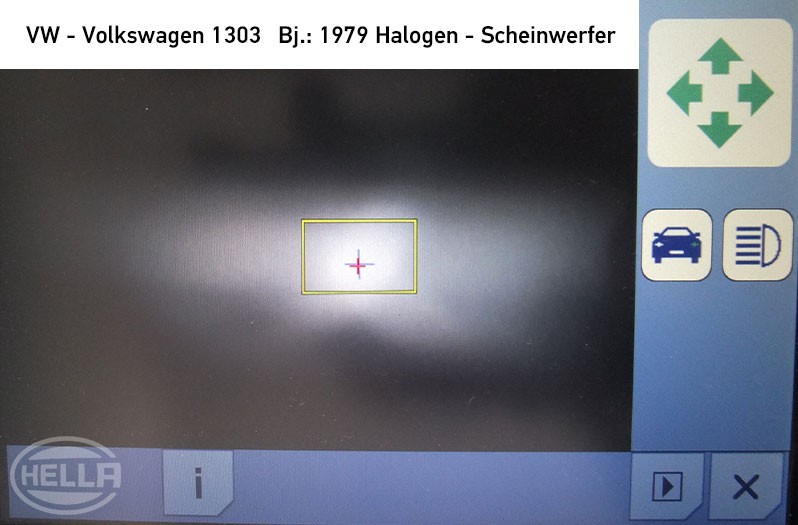

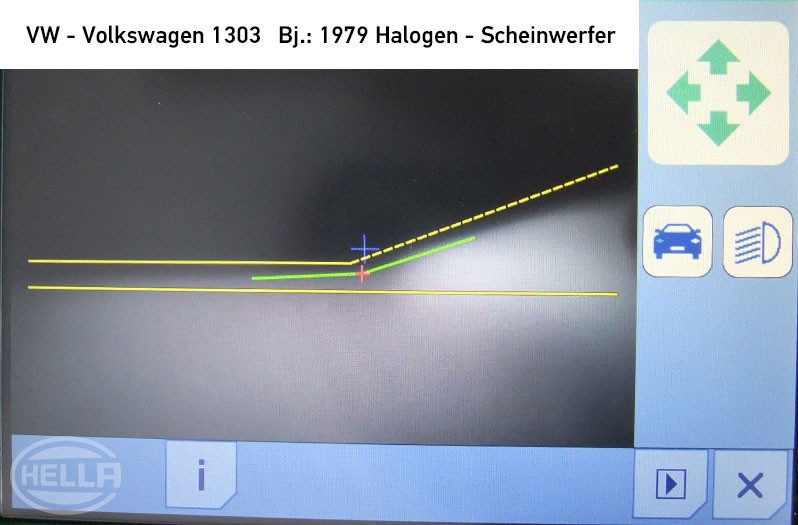

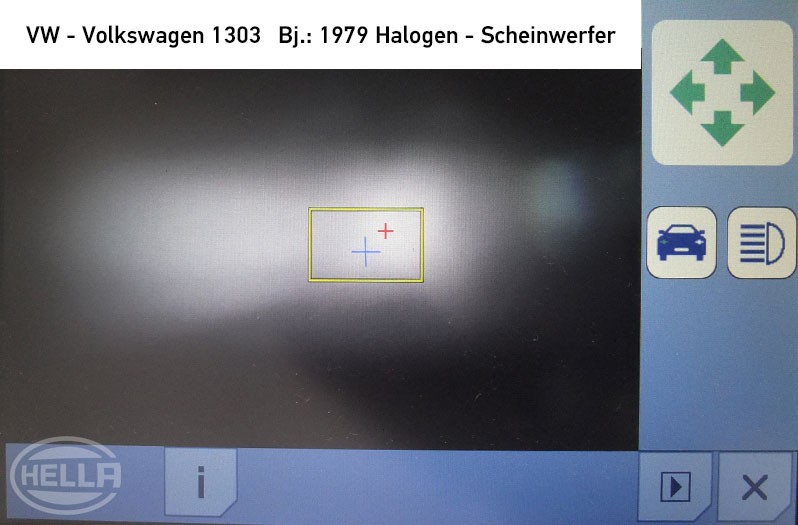

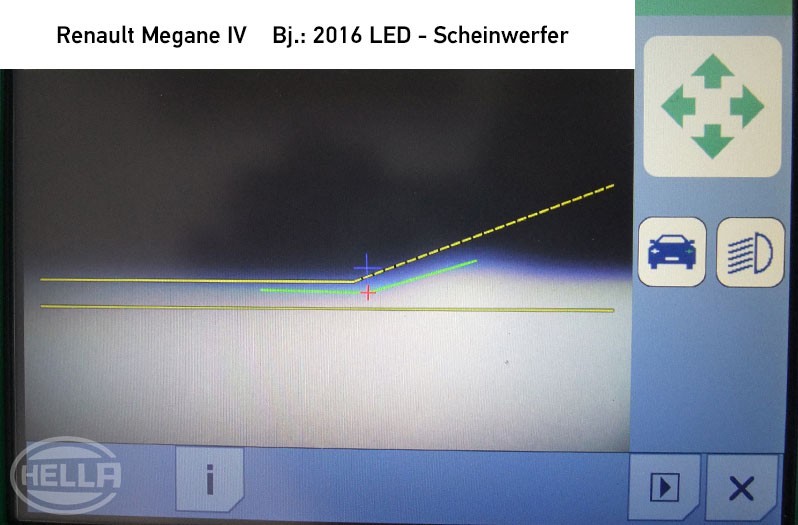

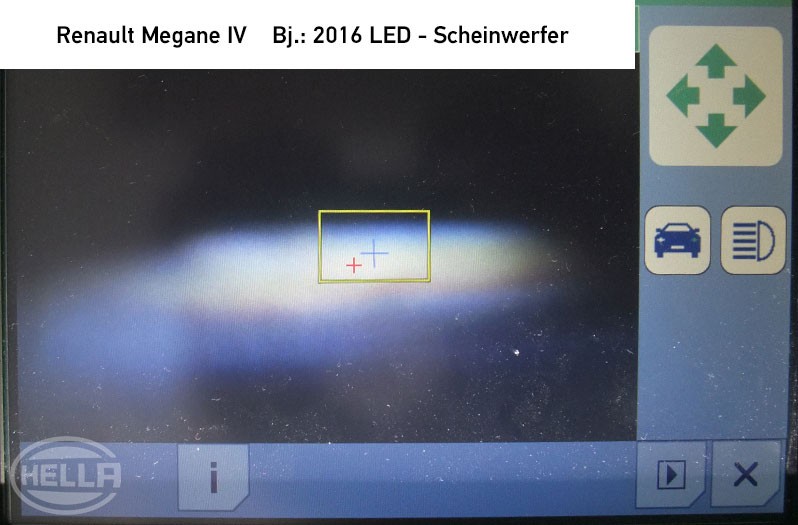

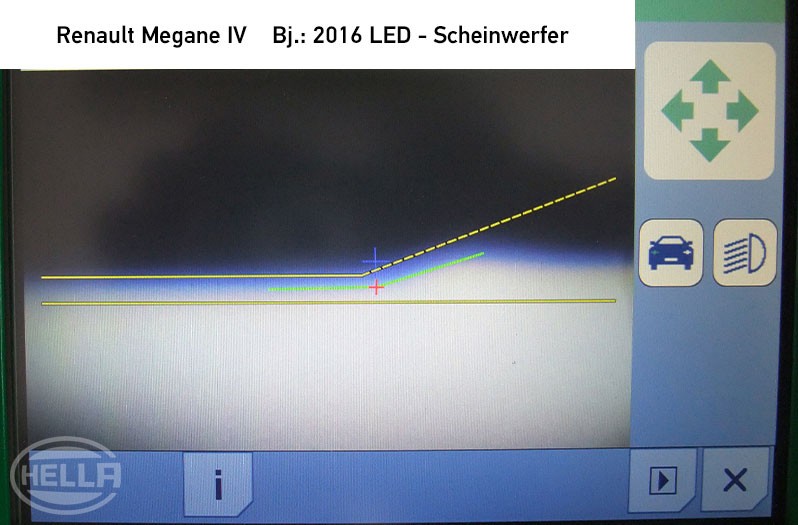

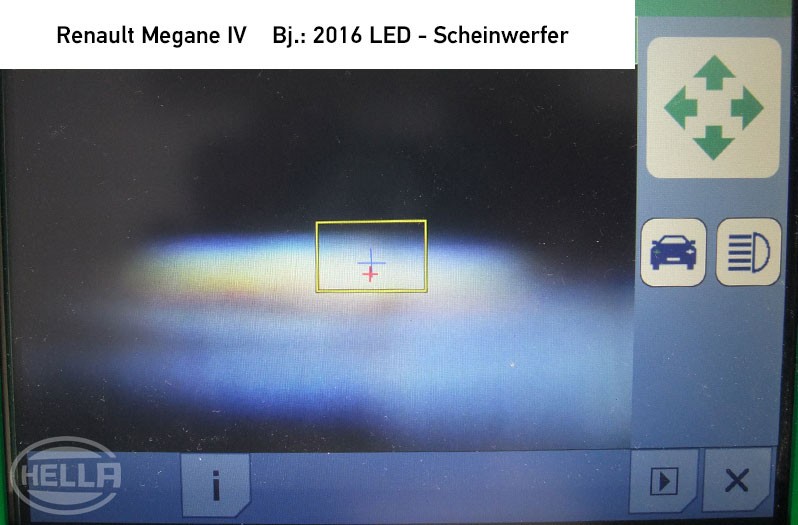

Measurement with the analogue SEG IV beamsetter from Hella Gutmann Solutions is carried out manually. The measurement was first carried out for the dipped beam and main beam of the left headlamp and then for the corresponding right headlamp.

In both cases, a perfect measurement result is obtained with the typical light distributions of this halogen H4 headlamp (see also the version above). There are no deviations requiring adjustment.