Headlamp levelling system

The load condition and pitching motion of the vehicle change the illumination range of the headlamps. This may dazzle other road users. This is why headlamp levelling systems (HLS) are legally prescribed. On this page, find out how standard market systems work, and how you can check them with simple means. Here, you can also learn what to do in the event of malfunction, and what you should note when adjusting headlamps with an automatic HLS.

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

Manual headlamp levelling systems

Automatic headlamp levelling systems

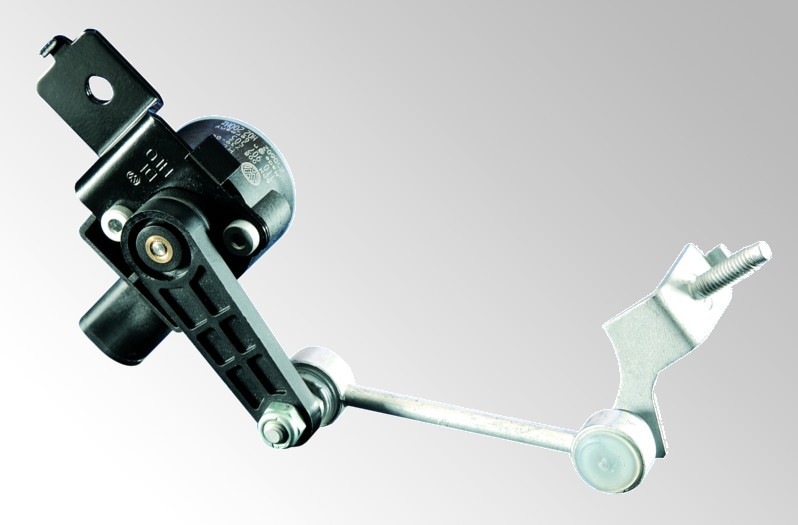

Design of an automatic HLS

These headlamp levelling systems fulfil their task without driver activity. We differentiate between two systems: Semi-static and dynamic headlamp levelling.

Usually the same type of actuator motors are used as for manual headlamp levelling systems. In the case of compact vehicles without long wheel overhang, this system offers the possibility of doing without the front axle sensor since the changes in inclination mainly occur on the rear axle only. In addition, semi-static headlamp levelling works with great damping, i.e. it only makes adjustments when the body is inclined for prolonged periods. In HELLA's xenon conversion sets an ultrasound system is used. Here, the sensor measures the direct distance to the road.

The block diagram shows the design of a dynamic headlamp levelling system. The control unit calculates the nominal data on the basis of the sensor data, taking the driving conditions into account. In contrast to semi-static headlamp leveling systems, the actuator motors are then triggered within fractions of a second. To make these quick response times possible, stepper motors are mainly used as actuators on the headlamps.

Tips for dealing with headlamp levelling systems

If there is an electrical fault in the headlamp levelling system during driving, the headlamps remain in this position. In other vehicles, though, the headlamps are moved to the home position and stay there. The driver is always alerted about the error by a signal light or a text message in the cockpit.

Defective headlamp levelling system

- Actuator motors on the headlamps are faulty

- Headlamp levelling system sensor for vehicle level is faulty

- Control unit has been replaced and not coded

- Headlamps have not been adjusted (basic setting)

- Control unit faulty

- Interrupted data cable

- No supply voltage

- Mechanical damage

Checking headlamp levelling systems

Function check

- Place the unloaded vehicle on an even surface.

- Align the beamsetter in front of the car and switch the low beam on. Check the correct cut-off line.

- Add a load to the rear end of the vehicle, e.g. by loading the trunk. With semi-static headlamp levelling, headlamp adjustment takes place after a few seconds and can be followed on the beamsetter. In the case of dynamic headlamp levelling, adjustment takes place extremely quickly, so that in the case of some vehicles the adjustment process is only perceived as a brief "flash" on the beamsetter test screen. For some vehicles, this adjustment happens only during driving, though.

If no adjustment process can be perceived, the following measurements should be carried out

- Check voltage supply to the actuator motors, the control unit, and the headlamp levelling system sensor.

- Check the headlamp levelling system sensor and data cable for mechanical damage and check correct installation position.

- Use the oscilloscope to check the sensor signal.

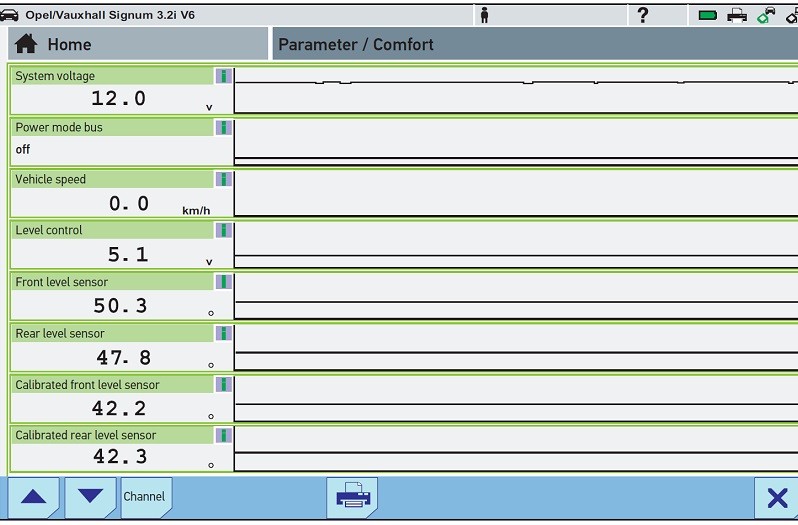

- Use a diagnostics tester to check the parameters and actual values.

Adjusting xenon headlight levelling systems

Compulsory headlamp levelling systems

Since 1993, new vehicles have been legally required to have a headlamp levelling system. The regulations can be found in the directives 76/756/EEC and ECE-R48.

How helpful is this article for you?

Success

Success

Success

Success

Error

Please tell us what you did not like.

Thank you for your feedback!

Wrong Captcha

Something went wrong

Further technical information