Headlamp cleaning system

Headlamp cleaning systems improve visibility in the dark and prevent dazzling of oncoming traffic through stray light. On this page, find out about the structure of headlamp cleaning systems and how they work. You can also find useful tips here on using these safety systems along with information on troubleshooting in the event of malfunction.

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

Headlamp cleaning system

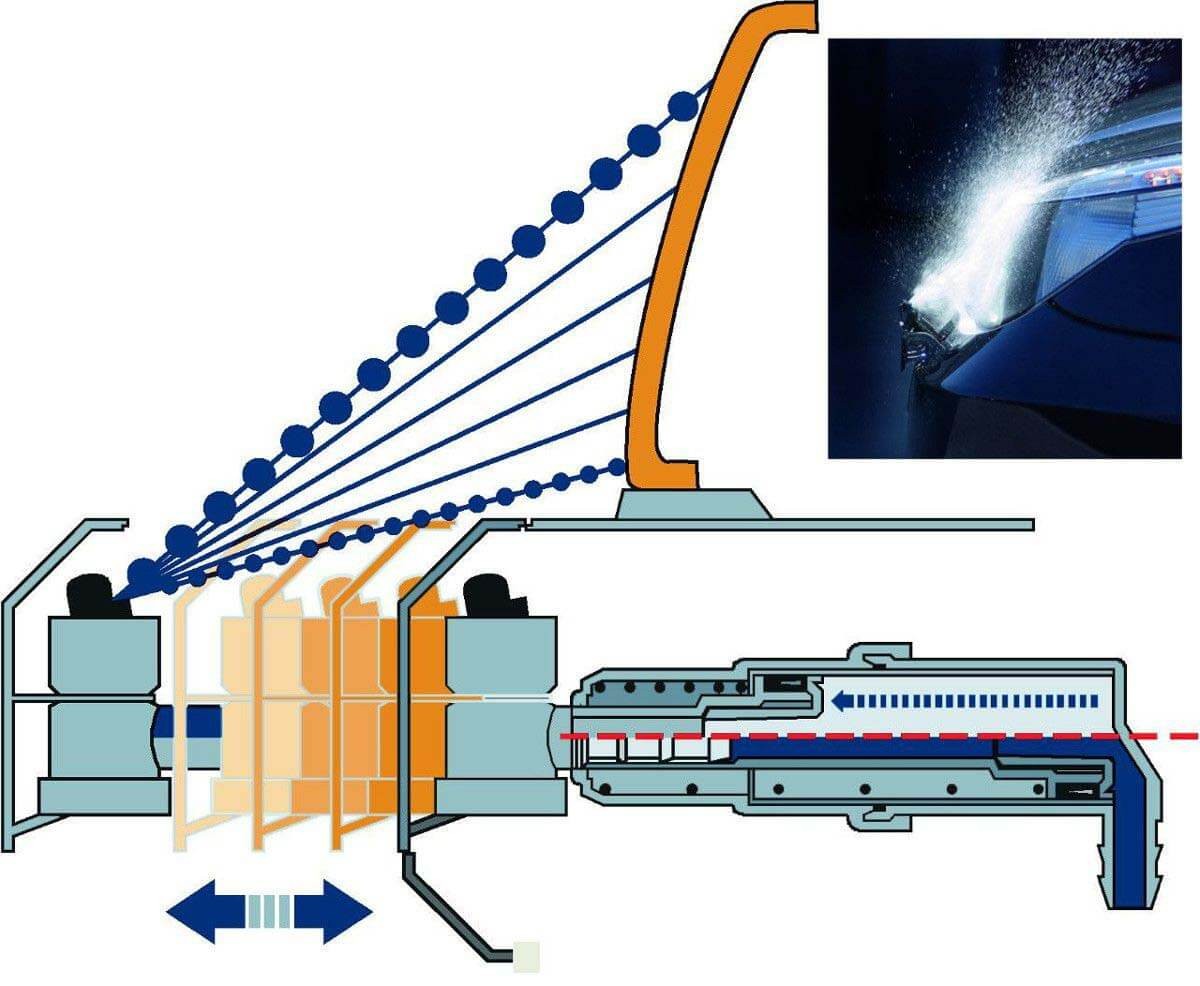

Headlamp cleaning system (hlcs) for cars

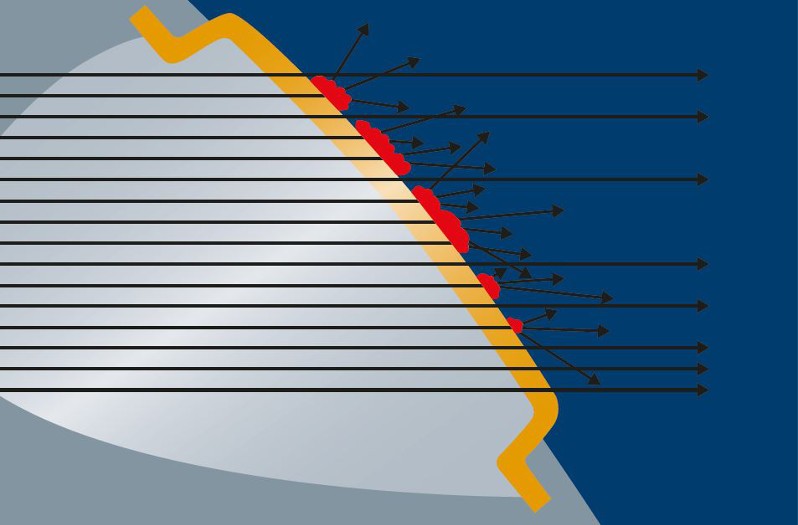

Cleaning principle

Tips on dealing with headlamp cleaning systems

When some cleaning agents are used, excess dosing can result in heavy foam formation since this effect is exaggerated even more by the whirl chamber nozzles.

- The foam can stick to the headlamp for some time, causing problems with the light distribution .

- For this reason care should always be taken to mix the water and cleaning agent to the right mixing ratio.

Faulty headlamp cleaning system

- Centrifugal pump is not working

- Leaky hose

- Blocked or faulty valve

- Blocked nozzle

- Damaged telescopic arm

Checking headlamp cleaning systems

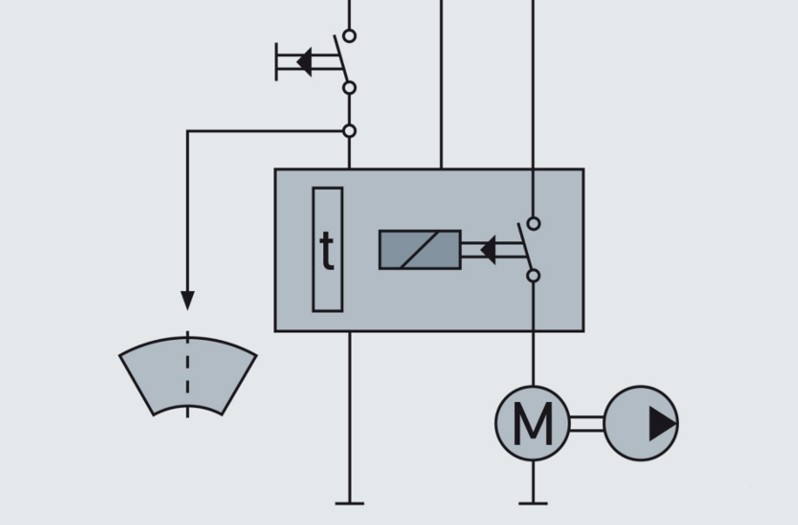

If the centrifugal pump does not work (noise can be clearly heard during normal operation) when the washing function has been activated, the voltage supply including the fuse must be checked.

If the water spray cone is only one-sided or extremely weak although the pump is working, this could be caused by the following:

Inverse polarity of the motor pump:

Check the polarity, since centrifugal pumps can work in both directions of rotation but with different hydraulic power.

System is not bled:

Bleed the system completely by activating the system several times without a break.

Hose is kinked or leaking:

Check the routing of the hose and change if necessary. Seal leaks and/or repair hose.

Nozzles or valves are blocked:

Remove foreign particles by rinsing the system.

Component parts are frozen up:

Increase amount of anti-freeze. Freezing will not damage the components, however.

If cleaning efficiency is still not as good as it should be, check the nozzle setting and/or set according to manufacturer's specifications.

Headlamp cleaning system obligation

For europe the main requirements are as follows:

- The cleaning systems are subject to type approval according to ECE R45 with regard to their cleaning power.

- The fitting of such systems when gas discharge lamps are used has been compulsory since 1996 in compliance with ECE R48.

- Water reserves for 25 or 50 cleaning cycles (class 25, class 50)

- Cleaning efficiency of > 70% on a headlamp that is dirty to such an extent that only 20% of the original luminous flux is available

- Functional capacity up to 130 km/h and from –10 °C to +35 °C

How helpful is this article for you?

Success

Success

Success

Success

Error

Please tell us what you did not like.

Thank you for your feedback!

Wrong Captcha

Something went wrong

Further technical information