Pinch the corroded crimp contacts off the cables

Pinch the corroded crimp contacts off the cables and dismantle the bulb holder from the light.

If headlamps or other vehicle lamps are fogged up on the inside, car drivers usually consider this to be a defect. However, in some cases this is a physical phenomenon. This page explains how this can come about. You will also find out what to do if water collects in the headlamp or other vehicle lamps. There is also a step-by-step guide for replacing faulty lamps, which provides a number of practical tips.

Important safety note

The following technical information and practical tips have been compiled by HELLA in order to provide professional support to vehicle workshops in their day-to-day work. The information provided on this website is intended for suitably qualified personnel only.

If humidity penetrates into a lighting system, the impairment to the light distribution or light output as perceived by the driver only represents the obvious effect. The corrosion caused by humidity is a much more serious problem in many cases. Whereas excessive fogging in headlamps and other lamps can be seen quickly, corrosion works in hidden spots. The whole extent of the “decay” only comes to light when diagnostics take place, e.g. when one of the light functions fails. Corroded plug connections, crimp contacts that have been oxidized away, and completely dilapidated bulb holders are only a few examples of what can be found. Compared with commercial vehicles and passenger cars, this subject is even more of an issue with motor homes and caravans. Here, penetrating humidity may not only damage the light and its wiring, it can also spread into the insulation of the bodywork, which can result in mold forming.

The most important points related to proper repairs will be explained using the example of various lamps on a motor home.

First, let us explain a few physical laws related to humidity in lighting systems. These can be used as basic information when talking to customers.

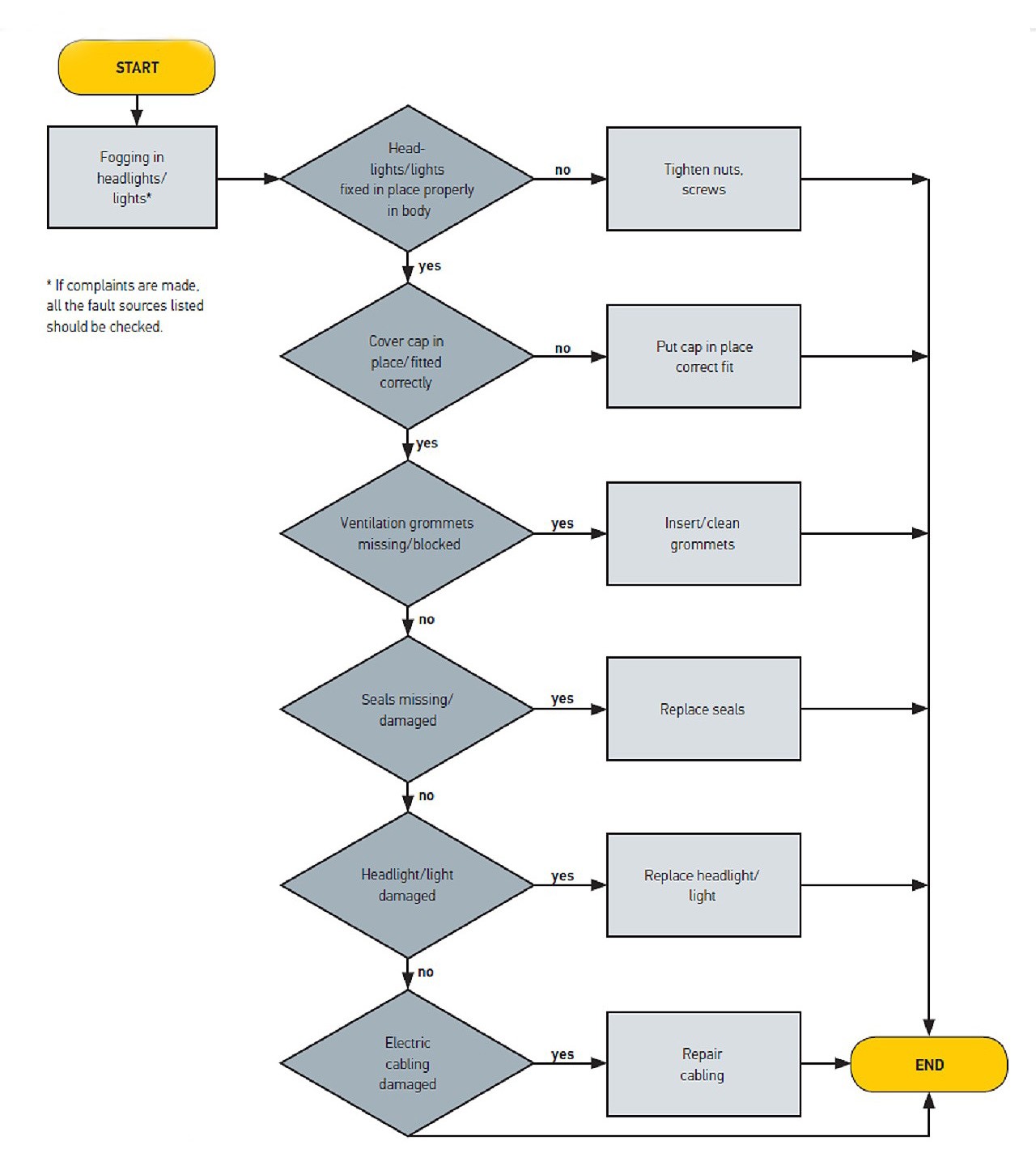

If a driver complains about heavy fogging on their vehicle’s lighting equipment, this can have several causes. A systematic procedure is thus essential to fast and reliable troubleshooting. The troubleshooting tree (see diagram) illustrates the main testing steps.

Pinch the corroded crimp contacts off the cables and dismantle the bulb holder from the light.

Pull suitable heat-shrinkable plastic tubing (pay attention to the diameter) over the cable near the cable duct and heat it using a hot air gun until it is tight against the cables.

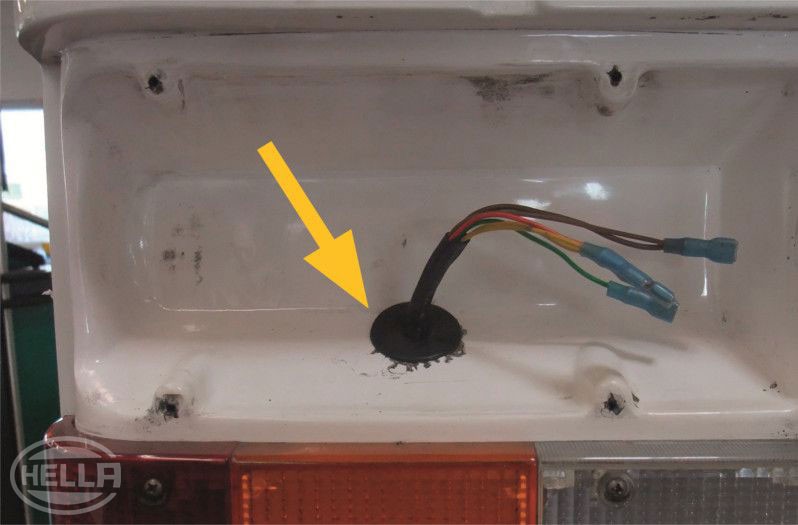

Various caravan and motor home manufacturers create a cable duct using a bore hole. If these are not sealed, rubber plugs can be used. These are offered in different sizes in kits and are versatile. Select a matching plug and put a hole through the centre. The diameter of the hole should be a little smaller than the diameter of the cable with heat-shrinkable plastic tubing. This ensures that no water can penetrate the interior between the heat-shrinkable plastic tubing and plug after the plug has been mounted.

Strip the cable ends to approx. 10 mm and fit crimp contacts e.g. HELLA no. 8KW 732 567-003. Then heat the shrink sleeves of the crimp contacts using a hot air gun until they are tight against the cable.

To prevent water and dirt penetrating the light as before, we recommend the use of thin strips of cellular rubber. These are available in a wide range of versions in terms of thickness and width. It is important that they have an adhesive coating on one side. Glue the cellular rubber strips all the way round the contact face of the light. A small section approx. 1 cm long should remain free at the lower edge to allow condensation etc. to flow away.

Fit light bulbs in the bulb holder and insert the crimp contacts.

Blast dirt out of the light using oil-free compressed air.

Mount the bulb holder on the light and then screw this to the body tightly again.

Use a suitable cleaning agent to remove sealant from the contact face.

Strip the cable ends to approx. 10 mm and fit crimp contacts e.g. HELLA no. 8KW 732 567-003. Then heat the shrink sleeves of the crimp contacts using a hot air gun until they are tight against the cable.

This side marker light does not have a rubber seal to the plastic body. This means water can find a way between the body and the light housing in this case, too. This process is enhanced by the airstream. For this reason, O-rings should be used as seals for recessed luminaires with a round lamp base. If there are no suitable O-rings available, have a look in your O-ring box for air-conditioning systems. Slide the O-ring up to the light's base plate.

Caution! The O-ring must not be too thick. After assembly, the light should be flush to the body.

Insert crimp contacts on the lamp base and screw the light tightly to the body again.

When lighting systems are installed or repaired with the right know-how and material, the effects of humidity can be reduced to the minimum possible under the physical conditions. This applies for most LED lamps, as well as for lamps with conventional bulbs fitted.

How helpful is this article for you?

Success

Success

Success

Success

Error

Thank you for your feedback!

Wrong Captcha

Something went wrong

Benefit from consenting to our cookies ‒ we use cookies to:

By clicking on "I agree", you consent to the placement of cookies.

You can find out more about the cookies used by HELLA websites in our Cookie Policy .

Our cookies do not contain any personal data.

For more information, see our data protection notice.

Great! Just one more Step

Head to your inbox and confirm your email address so that you don’t miss our updates!

Get ready for brand new technical videos, car repair advice, trainings, helpful diagnostic tips, marketing campaigns and much more... delivered straight to your inbox every two weeks!

Sign up for our free HELLA TECH WORLD newsletter to receive the latest technical videos, car repair advice, training, marketing campaigns and diagnostic tips.

Together we can get cars back on the road quickly!

Success

Success

Error

Please note:

You will only be subscribed to the newsletter once you have clicked on the confirmation link in the notification e-mail you will receive shortly!