New High Voltage PowerBox from FORVIA HELLA: Reduced costs and faster charging processes

- Combination of high voltage converter and onboard charger in one product; integration of battery management system and intelligent Power Distribution Module also possible

- Particularly high power density and high efficiency: more power with a compact product design reduces weight, increases efficiency and accelerates charging processes for electric vehicles

Lippstadt, 12 September 2024. The international automotive supplier FORVIA HELLA is expanding its portfolio in the area of power electronics for electric vehicles with a new High Voltage PowerBox (HV PowerBox). "In order for e-mobility to become even more established in society as a whole, it is particularly important that electric vehicles can be charged quickly, safely and efficiently, in addition to their range," says Jörg Weisgerber, Managing Director Electronics at FORVIA HELLA.

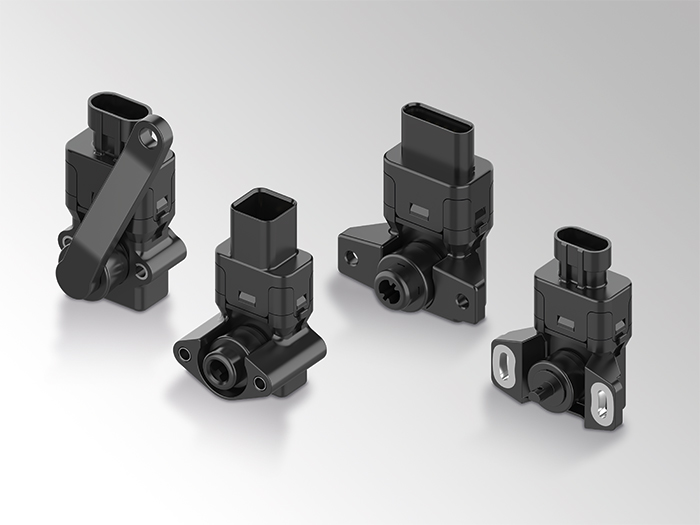

Against this backdrop, the HV PowerBox of FORVIA HELLA integrates a high voltage converter and an onboard charger in one product. While the onboard charger acts as an interface between the electric vehicle and the power grid, the high voltage converter transforms the 400 V or 800 V voltage into 12 volts so that the corresponding electronic consumers of the vehicle, especially safety-critical sensors or comfort functions, can be operated. The technology is expected to go into series production from 2027.

The approach to combine onboard charger and high voltage converter in one system results in a particularly high power density: With over 3 kW per liter of its volume, the HV PowerBox is designed to deliver more power in a smaller housing. In addition, the HV PowerBox from FORVIA HELLA achieves an overall efficiency of 97 percent. That means: Fewer losses occur during the charging process and the energy can be used more efficiently; this also reduces the electricity costs for charging.

The combination of voltage converter and onboard charger also reduces costs for materials, logistics and development and simplifies integration into the vehicle. The HV PowerBox is also designed with new housing technology, an innovative heating and cooling concept and an intelligent design, which is geared towards cost-optimized production in large quantities and leads to a significant reduction in weight of around 20 to 25 percent. Other key components for e-mobility can also be integrated into the HV PowerBox, such as a high-voltage battery management system, a secondary voltage converter, e-fuses or an intelligent Power Distribution Module (iPDM).

Electronics Managing Director Jörg Weisgerber: "We have been very successful in the power electronics business for over 15 years and are now one of the world's leading suppliers in this field. We produce around three million 48 V/12 V voltage converters per year, and next year we will launch the company's first high voltage converter in series production. We also set standards in terms of quality, reliability and automation, particularly in this extremely safety-relevant product area. With the development of the HV PowerBox, we are building on this extensive expertise and expanding our portfolio with another key component for electromobility and autonomous driving."

Contact

Press Officer

Rixbecker Str. 75

59552 Lippstadt

Phone: +49 2941 38-7566

Fax: +49 2941 38-477545